- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

2025 Top Plastic Processing Trends Transforming Manufacturing Innovations

As we look towards the future of manufacturing in 2025, the plastic processing industry stands on the brink of transformative innovations that promise to redefine production norms. According to Dr. Emily Carr, a leading expert in plastic processing technology, “The next wave of advancements will not only enhance the efficiency of manufacturing processes but also foster greater sustainability and adaptability in an ever-evolving market.” This sentiment underscores the significant shifts underway, driven by advancements in material science, automation, and eco-friendly practices.

The trends identified as the top ten in plastic processing are set to revolutionize how manufacturers approach design, production, and sustainability. These trends highlight a collective movement towards integrating smart technologies and reducing environmental impact, thus aligning with global goals for sustainability. As these innovations take root, they will pave the way for a new era in plastic processing, where agility and efficiency coalesce to create a more resilient manufacturing landscape.

In this context, understanding the upcoming trends not only provides insight into the competitive advantages for businesses but also emphasizes the critical role of innovation in fostering a sustainable future. With industry leaders like Dr. Carr advocating for these shifts, the plastic processing sector is poised for a remarkable evolution that will resonate throughout the broader manufacturing ecosystem.

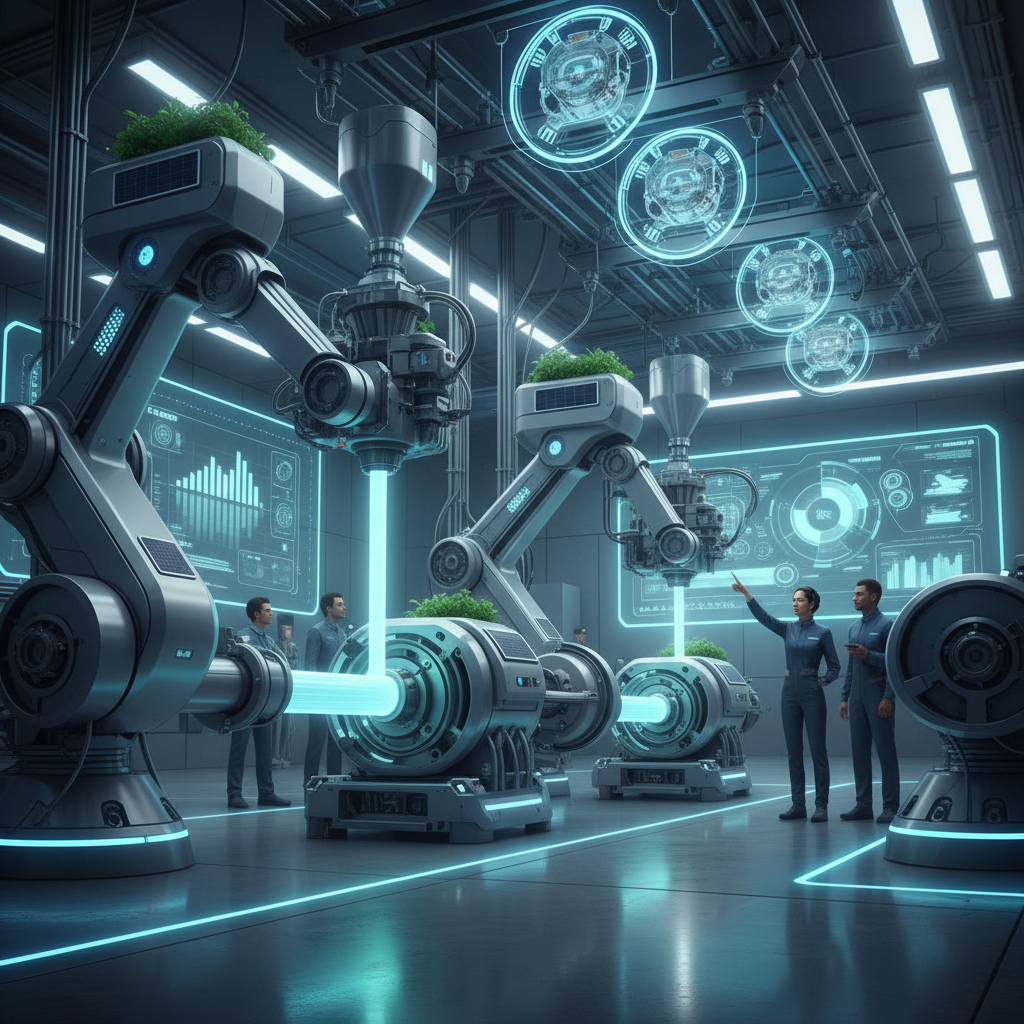

Emerging Technologies Driving Plastic Processing Efficiency in 2025

In 2025, the landscape of plastic processing will be dramatically reshaped by emerging technologies aimed at enhancing efficiency and sustainability. One of the most significant innovations is the integration of artificial intelligence (AI) and machine learning into production workflows. These technologies enable predictive maintenance, optimizing machinery performance and reducing downtime. By analyzing vast amounts of data in real time, AI can identify patterns that lead to equipment failures, allowing manufacturers to act proactively rather than reactively.

Another key driver of efficiency in plastic processing is the adoption of advanced automation and robotics. With the rise of smart factories, automated systems are increasingly employed to handle repetitive tasks, resulting in faster production cycles and greater precision. These robotics not only improve the quality of plastic components but also lower labor costs, paving the way for higher profit margins. Furthermore, innovations like 3D printing are expanding design freedom, enabling complex geometries that were previously unattainable with traditional methods. This convergence of technologies reflects a transformative shift towards a more agile and sustainable manufacturing environment in the plastic processing industry.

2025 Top Plastic Processing Trends Transforming Manufacturing Innovations

| Trend | Description | Emerging Technology | Efficiency Impact |

|---|---|---|---|

| Sustainability Practices | Incorporating renewable materials and reducing waste in production. | Bio-based plastics and recycling technologies. | Increases resource efficiency by up to 30%. |

| Automation and Robotics | Using automated systems for faster production rates. | AI and machine learning for process optimization. | Improves production efficiency by 40%. |

| Additive Manufacturing | Utilizing 3D printing technologies to create custom plastic products. | Fused deposition modeling and selective laser sintering. | Reduces material waste by 60%. |

| Smart Manufacturing | Integration of IoT for real-time monitoring of production processes. | IoT sensors and cloud computing. | Enhances process accuracy, increasing output by 20%. |

| Advanced Material Development | Innovating new plastic materials with enhanced properties. | Nanocomposites and thermoplastic elastomers. | Increases durability and reduces weight, enhancing product lifespan. |

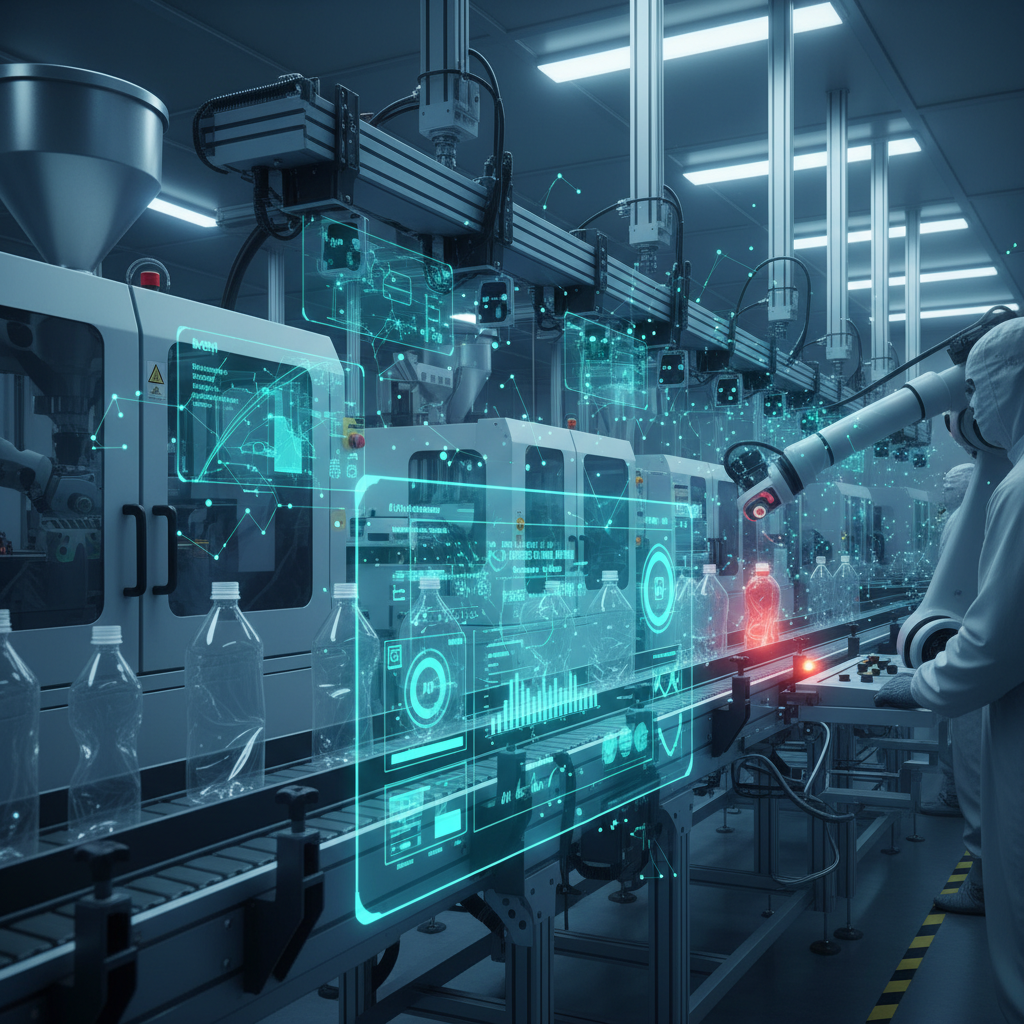

Integration of IoT and AI in Manufacturing for Enhanced Quality Control

The integration of the Internet of Things (IoT) and Artificial Intelligence (AI) in manufacturing is revolutionizing quality control processes in the plastic processing industry. IoT devices collect real-time data from production lines, enabling manufacturers to monitor operational efficiency and product quality throughout the manufacturing process. By utilizing sensors and smart machines, companies can detect anomalies and variations in production, allowing for immediate corrective actions. This proactive approach significantly reduces waste, minimizes downtime, and enhances overall productivity.

AI complements these IoT systems by providing advanced analytics and predictive maintenance capabilities. Machine learning algorithms analyze the data captured by IoT devices to identify patterns and predict potential failures before they occur. This minimizes disruptions and ensures that production meets quality standards consistently. Moreover, AI-driven quality control systems can learn from past data, continuously improving the inspection processes and ensuring that products meet stringent requirements. Together, IoT and AI create a seamless flow of information, empowering manufacturers to achieve higher levels of efficiency and quality in their plastic processing operations.

Sustainable Practices: The Rise of Biodegradable Plastics in the Industry

The rise of biodegradable plastics marks a significant shift in the manufacturing sector towards sustainability. These materials decompose into natural substances, such as water, carbon dioxide, and biomass, through microbial action involving bacteria, fungi, and algae. This accelerated degradation process allows biodegradable plastics to serve as a food source for microorganisms, addressing the pressing issue of plastic waste. As industries increasingly recognize the environmental impact of traditional plastics, the demand for innovative, sustainable alternatives is on the rise.

In the context of market dynamics, the molded fiber bowl market exemplifies a sector adapting to these eco-conscious trends. By utilizing materials like recycled cardboard, bagasse, and paper pulp, manufacturers are aligning with consumer expectations for environmentally friendly packaging solutions. This evolution reflects a broader industry commitment to reducing reliance on single-use plastics, offering both functional and sustainable options for food service and packaging applications. As we advance, the integration of biodegradable materials will play a crucial role in reshaping manufacturing practices, helping to combat the growing challenge of plastics pollution.

Additive Manufacturing: Revolutionizing Custom Plastic Solutions

Additive manufacturing, commonly known as 3D printing, is at the forefront of transforming custom plastic solutions in 2025. This innovative technology allows manufacturers to produce intricate designs and shapes that were previously unachievable with traditional methods. According to a recent report by SmarTech Analysis, the market for 3D printed plastics reached a staggering $1.2 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 23% through 2028. This growth is driven by the demand for customized products, enabling rapid prototyping and reducing material waste, thus enhancing sustainability in manufacturing.

TIPS: When considering additive manufacturing for plastic solutions, focus on selecting the right type of material based on the functional requirements of the end product. It's essential to utilize engineering-grade plastics that offer durability and performance for industrial applications. Additionally, investing in advanced 3D printing technologies can significantly improve production efficiency and reduce turnaround times.

Furthermore, the integration of AI and machine learning into additive manufacturing processes is streamlining production workflows. These technologies help optimize the design for manufacturability and enhance the precision of printed parts. Reports suggest that companies adopting AI-driven additive solutions see a reduction in production costs by up to 30%, which demonstrates the tangible benefits of embracing these innovations in the manufacturing landscape.

Digital Twins: Transforming Predictive Maintenance in Plastic Production

The manufacturing landscape is evolving rapidly, and digital twins are at the forefront of this transformation, particularly in the realm of plastic production. A digital twin serves as a virtual replica of physical assets, processes, or systems, enabling manufacturers to simulate, analyze, and optimize operations in real-time. In a recent report by Mordor Intelligence, the global market for digital twins is projected to grow from $3.1 billion in 2020 to $35.8 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 46.7%. This immense growth highlights the increasing importance of leveraging digital solutions to enhance manufacturing efficiency.

In the context of predictive maintenance, the integration of digital twins allows companies to anticipate equipment failures and reduce downtime. According to a study by McKinsey, predictive maintenance can lower maintenance costs by up to 30% and reduce equipment downtime by 50%. By utilizing this innovative technology in plastic processing, manufacturers can ensure continuous production flows and maintain high-quality standards while minimizing waste and operational costs. As businesses increasingly adopt Industry 4.0 principles, the role of digital twins in enhancing predictive maintenance will be critical in driving improvements and sustaining competitive advantage in the plastics manufacturing sector.

Related Posts

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency

-

Unlocking Creative Potential: How Color Master Batches Transform Plastic Manufacturing

-

Top 5 Benefits of Using Oxo Biodegradable Products for a Greener Future

-

Unlocking Creativity: How Special Effect Masterbatches Transform Modern Plastics with 30% Enhanced Visual Appeal

-

10 Essential Tips for Choosing the Right Polyethylene Masterbatch for Your Projects

-

Unlocking the Benefits of Anti Block Masterbatch: Revolutionizing Plastics with Enhanced Performance