- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

2025 Top Cable Compounds: Trends, Innovations, and Industry Insights

In the dynamic world of cable manufacturing, the selection and development of the right materials are paramount to ensuring performance and reliability. As the industry gears up for significant advancements in 2025, the focus on cable compounds has taken center stage. These specialized materials not only enhance the durability and efficiency of electrical and telecommunications cables but also play a critical role in meeting increasing demands for safety, environmental sustainability, and innovative functionality.

The forthcoming trends in cable compounds are shaped by technological innovations, regulatory changes, and evolving market needs. With the integration of new materials and processing techniques, manufacturers are finding ways to improve resistance to environmental factors, enhance electrical performance, and reduce overall costs. As we explore the landscape of 2025’s top cable compounds, it’s essential to understand the driving forces behind these innovations, as well as the implications for industry stakeholders. This insight will pave the way for advancements that not only meet current standards but also anticipate future challenges in the ever-evolving cable market.

Emerging Trends in Cable Compound Materials for 2025

As we move toward 2025, the cable compounds sector is witnessing notable innovations driven by the increasing demand for enhanced performance and sustainability. The market is projected to grow at a CAGR of 5.7% from 2023 to 2028, highlighting the urgency for manufacturers to adopt emerging materials that can better withstand environmental stressors. Polypropylene and thermoplastic elastomers are gaining traction due to their superior flexibility and resilience, making them ideal for both indoor and outdoor applications. According to a recent industry report, these materials are expected to hold 30% of the market share by 2025, reflecting a significant shift toward more versatile compounds.

Another critical trend is the integration of bio-based materials into cable compositions. A study from the International Journal of Polymer Science indicates that bio-based cable compounds can reduce carbon footprints by up to 40% compared to traditional petrochemical options. As companies strive to meet sustainability targets, the uptake of these materials is projected to increase, resulting in a compound forecast significantly skewed towards eco-friendly options in the coming years. The emphasis on recyclability and low environmental impact is not only a response to regulatory pressures but also an adaptation to changing consumer preferences focused on sustainability in all aspects of manufacturing.

Innovative Technologies Shaping the Future of Cable Compounds

The landscape of cable compounds is undergoing a significant transformation, driven by a wave of innovative technologies that are reshaping how cables are designed and manufactured. One of the most notable advancements is the integration of smart materials, which enhance the performance and durability of cables. These materials offer improved thermal stability and resistance to environmental stressors, ensuring that cables can function effectively in a variety of applications, from industrial settings to residential installations.

Additionally, advancements in recycling technologies are fostering sustainability within the cable industry. New processes allow for the efficient recovery of valuable materials from used cables, reducing waste and minimizing the carbon footprint associated with cable production. Coupled with this is the development of bioplastics, which are emerging as viable alternatives to traditional petroleum-based compounds. These innovations not only meet the growing demand for eco-friendly products but also align with global efforts toward sustainable development, making cable compounds more responsible and future-ready.

2025 Top Cable Compounds: Trends in Material Usage

Key Industry Players and Their Contributions to Cable Compounds

The cable compound industry is witnessing significant trends and innovations that are reshaping the landscape, particularly as major players continue to enhance their product offerings. In 2025, it is anticipated that the demand for high-performance cable compounds will escalate, driven by advancements in technology and the increasing need for durable and sustainable solutions. According to a recent market analysis report, the global cable compounds market is projected to grow at a CAGR of 5.6% from 2022 to 2029, emphasizing the urgency for industry players to innovate and adapt to changing market requirements.

Leading contributors in this sector are focusing on developing compounds with improved thermal stability, enhanced fire resistance, and reduced environmental impact. Recent statistics show that nearly 45% of industry players are investing heavily in R&D to create next-generation materials that comply with stringent regulatory standards while meeting the high-performance needs of various applications, including telecommunications and power distribution. Furthermore, eco-friendly materials are gaining traction, with studies indicating that such innovations could capture around 30% of the market by 2025, reflecting the shift towards sustainability in product development.

As the industry evolves, collaborations among key players are becoming more prevalent, enabling the sharing of technological advancements and accelerating product development cycles. This cooperative approach not only enhances innovation capacity but also fosters a more resilient supply chain. With continual improvements and a focus on customer needs, the cable compounds market is poised for a transformative journey that will shape the future of electrical infrastructure.

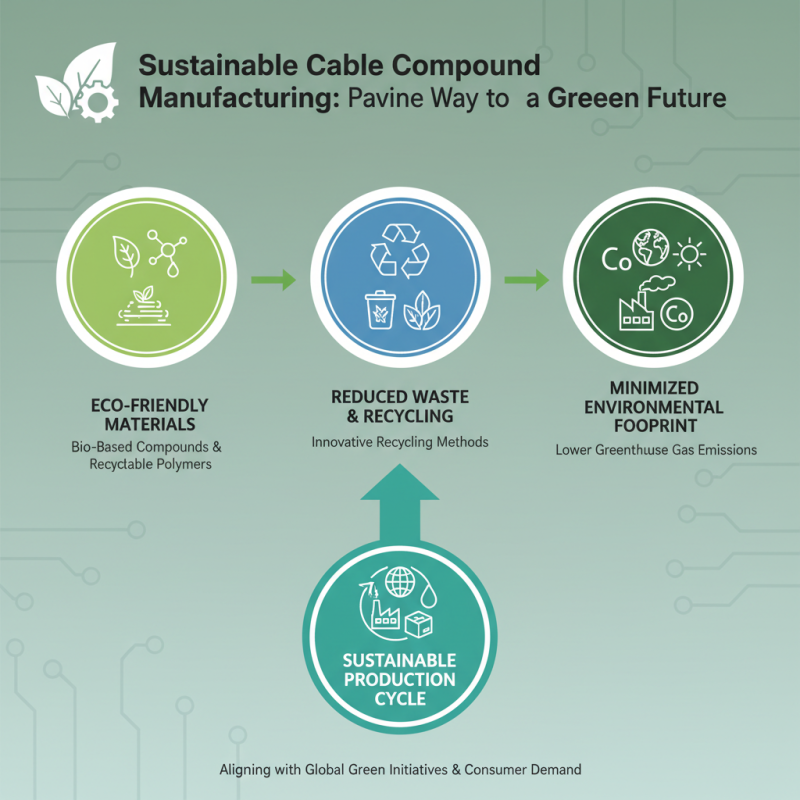

Sustainability Practices in the Cable Compound Manufacturing Process

As the cable compound manufacturing industry evolves, sustainability practices are becoming increasingly integral to its processes. Manufacturers are adopting eco-friendly materials and reducing waste through innovative recycling methods. By utilizing bio-based compounds and recyclable polymers, companies can minimize their environmental footprint, contributing to a more sustainable production cycle. This shift not only addresses the growing consumer demand for eco-conscious products but also aligns with global initiatives aimed at reducing greenhouse gas emissions.

Moreover, energy efficiency is gaining prominence in the manufacturing stages of cable compounds. Many facilities are investing in advanced technologies that require less energy and reduce carbon emissions. Implementing renewable energy sources, such as solar or wind power, further enhances sustainability efforts. Additionally, manufacturers are focusing on optimizing their supply chains to lessen transport-related emissions and promote local sourcing of materials. By fostering collaboration with suppliers that emphasize sustainable practices, the industry can significantly enhance its overall environmental performance, paving the way for a greener future.

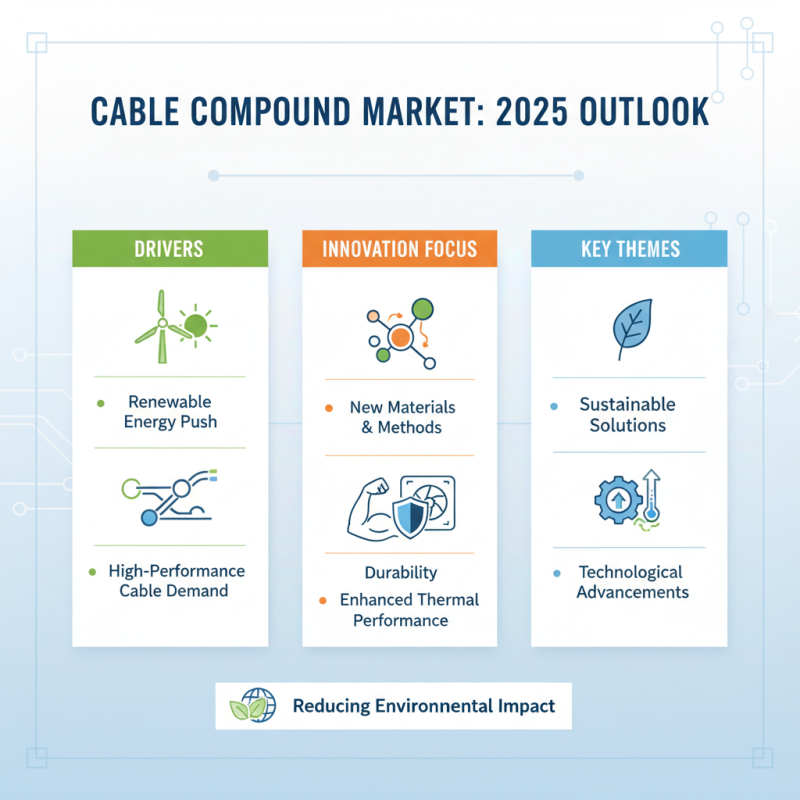

Future Forecast: The Cable Compound Market Outlook for 2025 and Beyond

As we look towards 2025, the cable compound market is poised for significant advancements driven by evolving technology and increasing demand for sustainable solutions. The push for renewable energy sources and the ever-growing need for high-performance cables create a unique landscape for innovation. Manufacturers are expected to explore new materials and methods, enhancing durability, flexibility, and thermal performance while reducing environmental impact.

Tips for navigating these market changes include staying informed on emerging material technologies, such as bio-based compounds and enhanced thermoplastics. Engaging with industry forums and trade shows can also provide valuable insights into best practices and revolutionary advancements. Additionally, considering the implementation of circular economy principles in your supply chain will not only align with regulatory expectations but also meet consumer demand for greener products.

As the global demand for telecommunication and power infrastructure continues to rise, companies that prioritize research and development in cable compounds will gain a competitive edge. Monitoring market trends and customer needs will be essential for adapting product offerings and ensuring long-term success. This proactive approach will help businesses thrive in an increasingly dynamic market while contributing to sustainable growth in the industry.

Related Posts

-

Top 10 Benefits of Using Compound Masterbatch in Plastics Manufacturing

-

Exploring the Fascinating World of Plastic Effects: How They Transform Our Everyday Materials

-

2025 Guide: How to Choose the Right Compound Filler for Your Projects

-

Exploring the Benefits of Compound Masterbatch: Industry Trends and Performance Metrics for 2024

-

Unlocking the Future of Plastics: How Anti Block Masterbatch Enhances Packaging Performance

-

Understanding Biodegradable Masterbatch: Benefits, Applications, and Innovations