- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

What is Optical Brightener Masterbatch and How is it Used?

Optical brightener masterbatch is an essential additive in the plastics industry. It enhances the brightness of plastic products and helps them appear cleaner and more vibrant. This masterbatch contains optical brightening agents that absorb ultraviolet light and emit visible light. As a result, it gives a whiter and brighter appearance to various materials.

The use of optical brightener masterbatch is widespread. Manufacturers use it in packaging, textiles, and consumer goods. It is especially popular in products like laundry detergents and plastics. However, not all applications yield the expected results. Some products may appear overly bright or unnatural. This effect can lead to customer dissatisfaction and returns.

Selecting the right optical brightener masterbatch is crucial. Different formulations exist for varying applications. It's essential to match the brightener with the type of plastic used. Otherwise, the outcome may not be ideal. Experimentation and testing are vital for achieving the best results. Users must reflect on their choices carefully.

Definition and Characteristics of Optical Brightener Masterbatch

Optical Brightener Masterbatch is a fascinating additive used in various plastic applications. It enhances the brightness of products, making them appear fresher and more vibrant. The core characteristic lies in its ability to absorb ultraviolet light. This absorbed energy is then re-emitted as visible blue light. This effect creates an illusion of whiteness, improving the overall aesthetic of the material.

These masterbatches contain high concentrations of optical brighteners. Typically, they are blended with polymers to create a uniform mixture. During production, careful attention needs to be paid to the temperature and mixing process. Achieving the right conditions is crucial. If not done correctly, the optical brighteners may not disperse evenly, leading to uneven coloring. This inconsistency is a common challenge that manufacturers face.

In practical applications, this masterbatch is commonly used in packaging materials, textiles, and household products. However, the effectiveness can vary based on environmental factors. For example, exposure to sunlight may degrade the brightener over time. This could lead to a gradual loss of brightness. It’s essential to consider these factors during production to ensure long-lasting results. The need for reflection on the application process is clear.

Applications of Optical Brightener Masterbatch in Various Industries

Optical brightener masterbatch is increasingly popular in various industries. This compound enhances the brightness of plastics, textiles, and paper products. In the textile industry, it accounts for approximately 15% of the total colorant market. Brands report a significant increase in product appeal when using optical brighteners.

In the plastic industry, optical brighteners improve aesthetics and visibility. They can increase the reflectivity of products by up to 30%. This effect is crucial in packaging, where visibility can influence purchasing decisions. Some manufacturers note that specific applications can lead to a reduced need for additional dyes, saving costs. However, many products still face challenges with uniform application.

In the paper industry, optical brighteners help create high-quality white papers. Around 45% of new papers use these additives. This usage often leads to concerns about environmental impacts. There are ongoing debates on sustainability and recyclability. These issues prompt manufacturers to seek alternative solutions while still wanting bright, appealing products. The quest for balance continues.

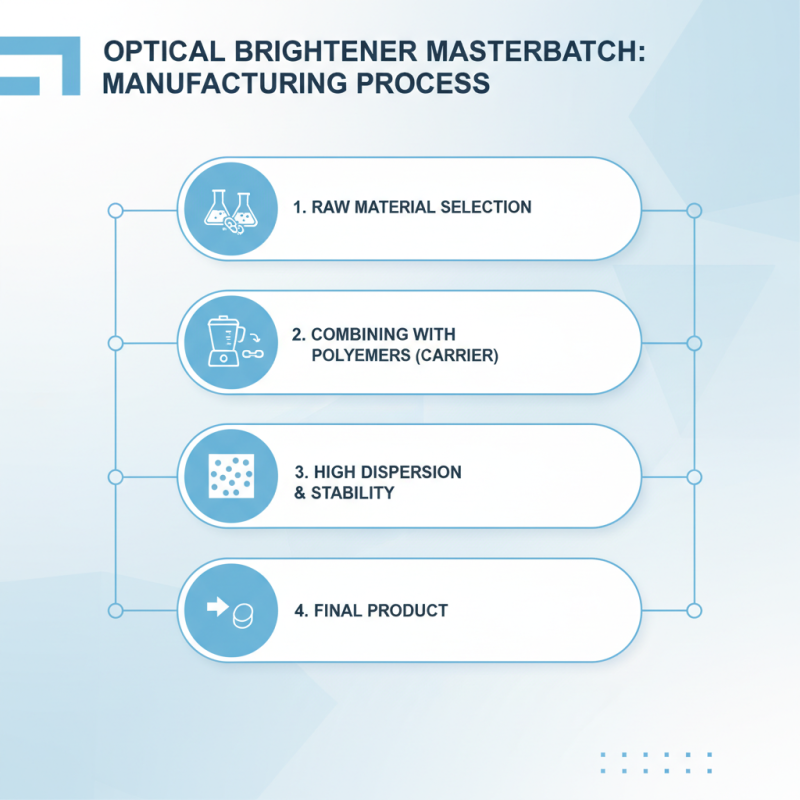

The Manufacturing Process of Optical Brightener Masterbatch

The manufacturing process of optical brightener masterbatch involves several critical steps. Initially, raw materials are carefully selected to ensure the desired optical properties. These materials are often combined with polymers that serve as carriers. This combination is crucial for achieving high dispersion and stability in the final product.

Once the materials are chosen, they are blended and processed using specialized equipment. Extruders play a vital role in this phase. They melt the mixture and create a homogeneous masterbatch. Achieving the right temperature is essential during this process. Too high or low temperatures can affect the performance of the optical brightener.

Cooling the masterbatch is another important step. It helps solidify the product and lock in the brightening agents. After cooling, the masterbatch is often pelletized for easier handling. Quality control checks follow to ensure consistent brightness. However, this stage can sometimes reveal imperfections that need to be addressed. Manufacturers constantly strive for improvements to enhance the quality and efficiency of their processes.

Advantages of Using Optical Brightener Masterbatch in Plastics

Optical brightener masterbatch is gaining traction in the plastics industry. This compound enhances the brightness of products through fluorescence. Its use leads to vibrant colors and visually appealing finishes. According to a recent industry report, the use of optical brighteners can increase the perceived whiteness of plastic materials by up to 50%. This makes products more appealing to consumers.

One significant advantage of optical brightener masterbatch is its ability to improve aesthetics without compromising quality. Many manufacturers report improved customer satisfaction due to enhanced visual appeal. Brightened products often stand out in a crowded market. However, there are challenges. Overuse can lead to color inconsistencies and unexpected fluorescent effects. Manufacturers must balance brightness with quality assurance.

Additionally, sustainability concerns arise from the use of certain brighteners. They may not always be eco-friendly. As regulations tighten, alternatives are in demand. Research shows that up to 30% of brighteners can be replaced with bio-based options. The shift toward sustainable solutions reflects consumer preference for greener products. Thus, while optical brightener masterbatch offers significant advantages, careful consideration of its long-term impact is essential.

What is Optical Brightener Masterbatch and How is it Used? - Advantages of Using Optical Brightener Masterbatch in Plastics

| Dimension | Value |

|---|---|

| Optical Brightener Type | Fluorescent Whitening Agents (FWAs) |

| Application Areas | Packaging, Automotive, Consumer Goods |

| Typical Concentration | 0.5% - 5% in Masterbatch |

| Benefits | Enhanced Brightness, Increased Whiteness, UV Protection |

| Polymer Compatibility | PP, PE, PS, PVC |

| Processing Temperature | 220°C - 280°C |

| Light Fastness | Good (Durable under UV exposure) |

| Environmental Consideration | Readily biodegradable variants available |

Safety and Environmental Considerations of Optical Brighteners

Optical brighteners, used in various products, enhance brightness. However, safety and environmental considerations are crucial. Many brighteners belong to a class of chemicals that can cause skin irritations. Personal protective equipment is often recommended during handling. It’s important to evaluate exposure levels, especially in industrial settings.

The environmental impact of optical brighteners is a complex issue. These compounds can accumulate in water systems, affecting aquatic life. Studies have shown that they can disrupt ecosystems. Not all brighteners biodegrade readily, raising concerns about long-term pollution. Responsible disposal practices are vital to minimize risks.

In recent years, there have been shifts toward eco-friendlier formulations. Yet, some manufacturers still rely on traditional brighteners. As awareness grows, the industry faces challenges in balancing performance with safety. Continued research is essential to develop safer alternatives. This ongoing journey requires critical reflection on our choices.

Usage of Optical Brighteners in Different Industries

Related Posts

-

Unlocking the Benefits of Anti Block Masterbatch: Revolutionizing Plastics with Enhanced Performance

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency

-

What is a Compound Cable and How Does It Improve Electrical Connections

-

10 Essential Tips for Choosing the Right Polyethylene Masterbatch for Your Projects

-

2025 Top Plastic Processing Trends Transforming Manufacturing Innovations

-

2025 Guide: How to Choose the Right Compound Filler for Your Projects