- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

Ultimate Guide to Choosing the Right Compound Masterbatch for Your Projects

In the ever-evolving world of plastics, selecting the right compound masterbatch is crucial for achieving optimal performance in various applications. As industry expert Dr. Emily Johnson, a renowned polymer scientist, once stated, “The effectiveness of a plastic product often hinges on the precise choice of compound masterbatch, as it directly influences both functionality and aesthetic appeal.” This insight underscores the importance of understanding the various types of compound masterbatches available and their specific attributes.

Choosing the right compound masterbatch for your project can seem daunting due to the myriad of options and formulations. Each application may require distinct properties, such as color, durability, or processing characteristics, and the success of the final product relies heavily on these decisions. Therefore, this ultimate guide aims to provide a comprehensive overview of how to strategically select the most suitable compound masterbatch while considering performance, cost, and environmental factors.

As we delve into this essential topic, we will explore the various types of compound masterbatches, their applications, and best practices for selection, ensuring that your projects achieve both quality and efficiency. Understanding the nuances of compound masterbatch selection is not just beneficial; it is imperative for anyone looking to innovate within the plastics industry.

What is a Compound Masterbatch and Its Importance in Manufacturing?

A compound masterbatch is a concentrated mixture of pigments, additives, and carrier materials that is distributed in the manufacturing process to enhance the properties of plastic products. This versatile product plays a crucial role in various industries, especially in plastic manufacturing, where consistent coloration, enhanced performance, and cost-effectiveness are essential. The importance of compound masterbatch lies in its ability to improve the processing characteristics of plastics while ensuring that the end products exhibit the desired physical and aesthetic qualities.

In manufacturing, the use of compound masterbatch allows for better control over the final product's characteristics. It enables manufacturers to achieve uniform color distribution, which is vital for aesthetic appeal. Additionally, the incorporation of specific additives within the masterbatch can lead to improvements in thermal stability, UV resistance, and other functional properties, making the end product more suitable for its intended application. Ultimately, selecting the right compound masterbatch is critical for optimizing production efficiency, reducing material waste, and enhancing the overall quality of the finished items.

Types of Compound Masterbatches: An Overview of Available Options

When it comes to selecting the right compound masterbatch for your projects, understanding the different types available is crucial. Compound masterbatches are typically categorized into color masterbatches, additive masterbatches, and filler masterbatches, each serving specific functions in the production process. For instance, color masterbatches allow for the customization of plastic products with vibrant hues, while additive masterbatches enhance properties such as UV stability, flame retardancy, or antibacterial qualities. According to industry reports, the global masterbatch market is expected to reach a valuation of approximately $13.5 billion by 2027, underlining the rising demand driven by various sectors including packaging, automotive, and consumer goods.

In choosing the right compound masterbatch, consider the specific requirements of your application. The compatibility with the polymer matrix, the processing temperature, and the desired final properties are essential factors to evaluate. Additionally, opting for high-quality masterbatches can significantly reduce the risk of variability in production.

Tips: Always conduct compatibility tests before committing to a masterbatch solution. This ensures that the selected masterbatch not only meets aesthetic demands but also maintains the integrity and performance of your materials. Regularly consulting industry expertise and reports can also help keep you informed on innovations and trends that may influence your masterbatch selection strategy.

Ultimate Guide to Choosing the Right Compound Masterbatch for Your Projects

| Type of Compound Masterbatch | Color | Application | Advantages | Typical Usage Percentage |

|---|---|---|---|---|

| Black Masterbatch | Black | Film, Sheet, Injection Molding | Excellent UV resistance and thermal stability | 2-4% |

| White Masterbatch | White | Packaging, Toys, Housewares | High opacity and brightness | 3-10% |

| Color Masterbatch | Varied | Injection Molding, Blow Molding | Wide range of colors, customizable | 1-5% |

| Additive Masterbatch | Colorless | Polymer Modification | Improves processing properties and performance | 0.5-3% |

| Special Effect Masterbatch | Metallic, Pearl, Glitter | Decorative Applications | Unique visual effects and aesthetics | 2-7% |

Key Factors to Consider When Selecting a Compound Masterbatch

When selecting a compound masterbatch for your projects, several key factors must be carefully evaluated to ensure optimal performance and compatibility with your application requirements. One significant aspect to consider is the specific characteristics of the base polymer. According to a recent report published by Smithers, the global market for masterbatches is projected to reach over $20 billion by 2026, emphasizing the importance of choosing the right formulation to achieve desired properties such as processing temperature and mechanical strength. Understanding the interaction between the masterbatch and the polymer matrix plays a crucial role in achieving end-product quality.

Additionally, the selection of additives within the compound masterbatch can greatly influence the final product's performance. Fillers, pigments, and various functional additives serve to enhance properties like UV stability, color consistency, and impact resistance. Industry trends suggest that sustainable practices are becoming increasingly prioritized, with companies actively seeking bio-based or environmentally friendly options. As reported by Plastics News, nearly 30% of consumers are willing to pay a premium for products made with sustainable materials. Thus, aligning your choice of masterbatch with sustainability goals can improve your project's marketability while meeting regulatory expectations.

Ultimate Guide to Choosing the Right Compound Masterbatch

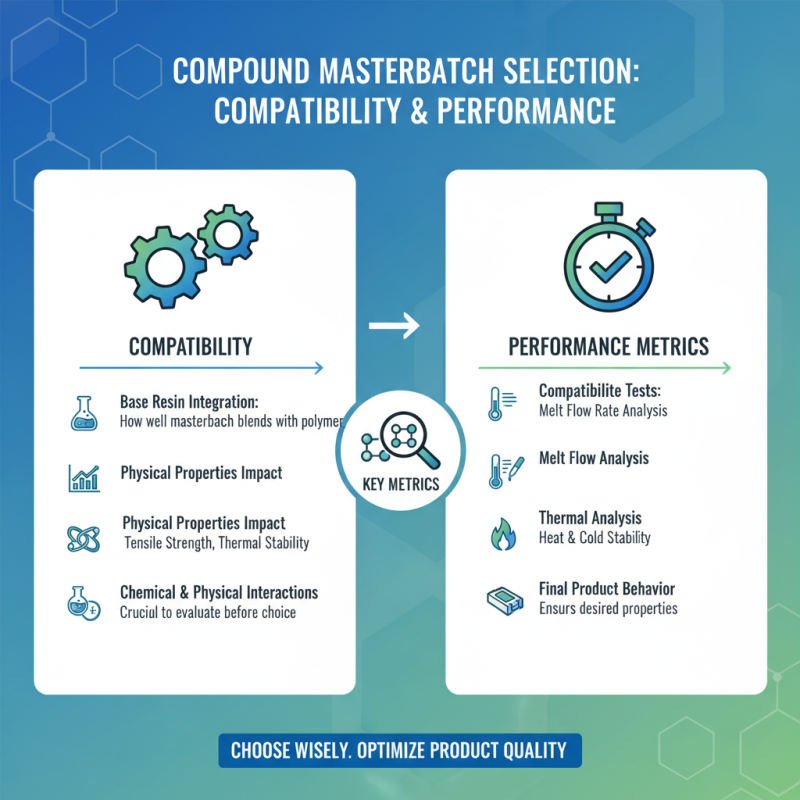

Understanding Compatibility and Performance Metrics for Masterbatches

When selecting a compound masterbatch for specific projects, understanding compatibility and performance metrics is crucial. Compatibility refers to how well the masterbatch integrates with the base resin or polymer system. This integration affects the physical properties of the final product, including clarity, tensile strength, and thermal stability. Different polymers can react in varied ways when combined with specific additives found in masterbatches, making it necessary to evaluate the chemical and physical interactions before making a choice. Conducting compatibility tests, such as melt flow rate analysis or thermal analysis, can provide insight into how well the chosen masterbatch will perform in conjunction with the base material.

Furthermore, performance metrics play a vital role in determining the suitability of a compound masterbatch. These metrics include color strength, dispersion quality, and processing behavior. A high-quality masterbatch should demonstrate uniform dispersion within the polymer matrix, which directly impacts the aesthetic and functional attributes of the final product. Additionally, the processing characteristics, like melt viscosity and temperature stability, should align with the manufacturing process used, whether it's extrusion, injection molding, or blow molding. Evaluating these performance metrics not only helps in selecting the right masterbatch but also ensures that the final products meet the desired specifications and standards of quality.

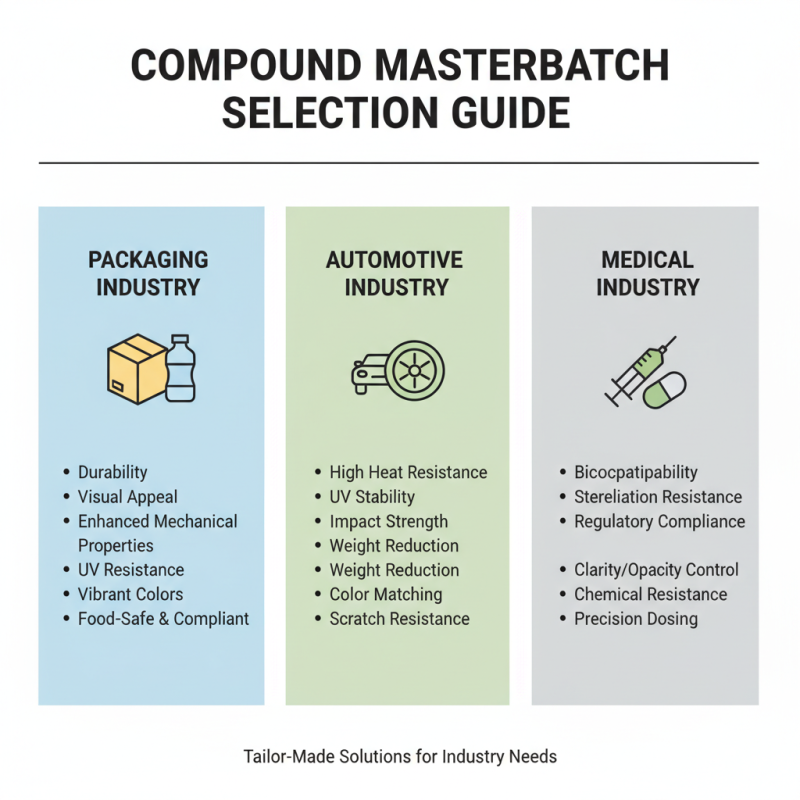

Application-Specific Considerations for Different Industries and Projects

When selecting the right compound masterbatch for specific applications, it is crucial to consider the unique requirements of various industries. For instance, in the packaging industry, where durability and visual appeal are paramount, incorporating masterbatches that enhance mechanical properties, UV resistance, and vibrant colors will ensure the final product meets consumer expectations. Additionally, food-safe and compliant materials are essential in food packaging, necessitating a thorough understanding of regulatory standards to avoid any health risks.

In the automotive sector, the focus shifts to performance and longevity. Masterbatches used in this industry should provide enhanced thermal stability, impact resistance, and color stability under varying environmental conditions. Furthermore, as sustainability becomes an increasing priority, the selection of bio-based or recycled materials as part of the masterbatch can significantly influence both product performance and the brand's environmental footprint. Each industry imposes its own set of demands, making it imperative to evaluate the specific properties required to ensure efficacy and compliance with industry standards.

Related Posts

-

Unlocking the Potential of Filler Masterbatch: Innovations in Polymer Manufacturing

-

What is Color Masterbatch and How It Transforms Plastic Manufacturing

-

How to Choose the Right Plastic Color Masterbatch for Your Projects

-

Top 10 Benefits of Using Compound Masterbatch in Plastics Manufacturing

-

Unlocking Creativity: How Special Effect Masterbatches Transform Modern Plastics with 30% Enhanced Visual Appeal

-

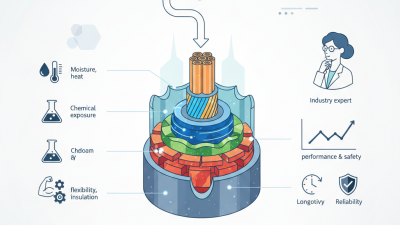

Why Choose the Right Cable Compound for Your Electrical Projects?