- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

Top 10 Tips for Efficient Plastic Processing in Manufacturing

In the competitive landscape of manufacturing, efficient plastic processing plays a crucial role in optimizing production workflows and maximizing output. As industries increasingly rely on plastic materials for their versatility and durability, the demand for streamlined processing techniques becomes ever more essential. This introduction highlights the significance of refining plastic processing methods to enhance not only product quality but also operational effectiveness.

Manufacturers face numerous challenges in the realm of plastic processing, including long cycle times, material waste, and energy consumption. Addressing these issues not only contributes to cost savings but also supports sustainable practices within the industry. By implementing best practices and innovative technologies, companies can significantly improve their plastic processing capabilities, leading to increased productivity and profitability.

In this article, we present the top ten tips for achieving efficient plastic processing in manufacturing. These insights will provide valuable guidance for manufacturers looking to refine their processes, reduce inefficiencies, and ultimately deliver superior plastic products to the market. By focusing on these key strategies, companies can position themselves for success in an increasingly demanding manufacturing environment.

Best Practices for Selecting the Right Plastic Materials in Manufacturing

In the ever-evolving manufacturing landscape, selecting the right plastic materials is paramount to achieve efficiency and sustainability. According to a report by the Plastic Industry Association, the U.S. plastics industry contributes over $400 billion to the economy, highlighting the importance of material selection for optimizing production processes and costs. Manufacturers must consider the mechanical properties, thermal stability, and chemical resistance of plastic materials to ensure compatibility with their intended applications.

When it comes to selecting the right plastic, remember to prioritize materials that provide the best balance of performance and cost. For instance, understanding the differences between thermoplastics and thermosetting polymers can significantly impact the manufacturing process. Thermoplastics such as polypropylene and polycarbonate offer flexibility in processing, making them ideal for various applications. Moreover, integrating recycling options into material selection can not only reduce waste but also enhance the sustainability profile of the production process.

Furthermore, leveraging advanced simulation tools can aid in predicting material behavior under different processing conditions. Investing in these technologies can minimize trial-and-error in selecting materials, ultimately speeding up the production timeline. According to industry data, companies adopting simulation during the design phase experience up to a 30% reduction in product development time. By embracing these best practices, manufacturers can optimize their processes and improve overall efficiency while ensuring that they choose plastic materials that meet the rigorous demands of modern applications.

Essential Equipment for Streamlined Plastic Processing Operations

Efficient plastic processing operations are heavily reliant on the right equipment, which can significantly enhance productivity and streamline workflows. One of the most essential pieces of machinery in this realm is the injection molding machine. This device allows manufacturers to produce complex shapes with precision and speed, making it invaluable for high-volume production runs. Coupled with advanced temperature control systems, these machines ensure optimal melting and molding conditions, which is crucial for maintaining material consistency and reducing waste.

Moreover, auxiliary equipment such as granulators and mixers play a pivotal role in preparing raw materials for the manufacturing process. Granulators are designed to break down large plastic waste into smaller, manageable sizes, facilitating recycling and reducing costs. Meanwhile, mixers ensure that additives are uniformly blended with the base resin, which is vital for achieving desirable performance characteristics in the final product. Together, these tools create a more efficient processing environment, allowing manufacturers to meet high demand while maintaining quality standards. By investing in the right equipment, companies can significantly enhance their operational efficiency and competitiveness in the plastic manufacturing industry.

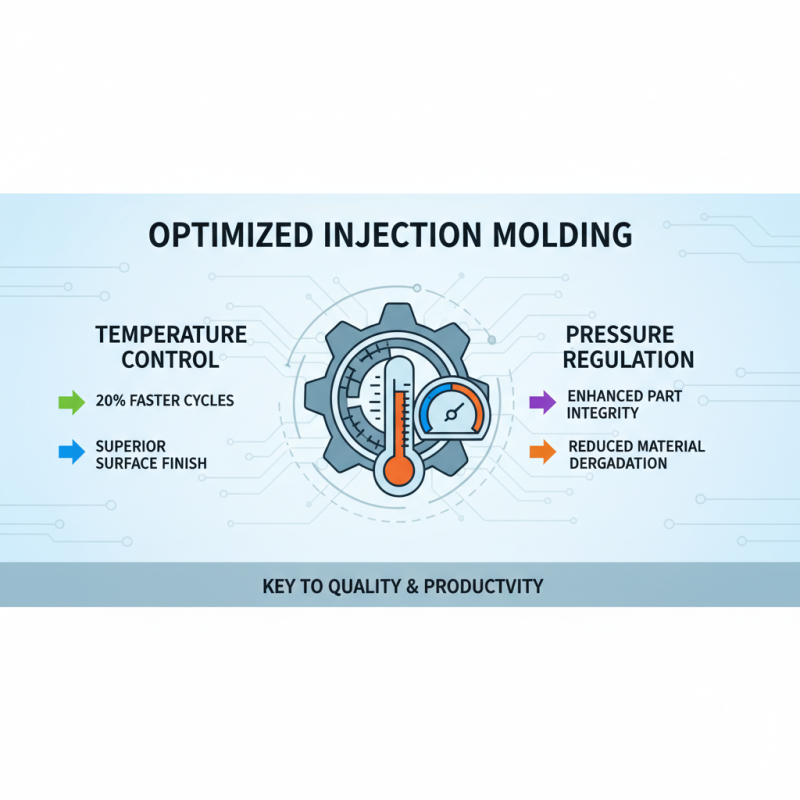

Techniques for Optimizing Temperature and Pressure in Injection Molding

Efficient plastic processing in manufacturing is crucial for enhancing product quality and overall operational productivity. One of the most effective ways to achieve this is through optimizing temperature and pressure during injection molding processes. Industry reports indicate that the right temperature settings can lead to a 20% reduction in cycle times while maintaining part integrity. Utilizing precise temperature control also minimizes material degradation, resulting in superior surface finish and mechanical properties.

To achieve optimal temperatures, it’s essential to regularly calibrate heating elements and monitor material viscoelasticity. Integrating real-time sensors can provide critical feedback and adjustments to maintain ideal conditions. A study from the Society of Plastics Engineers revealed that maintaining an optimal melt temperature can enhance fill rates and reduce the likelihood of defects such as warping or short shots.

Pressure optimization is equally important, as it can significantly impact the filling phase and the final quality of molded parts. Applying the correct injection pressure is vital; exceeding levels can cause flash and degrade resin quality. Implementing a stepwise pressure profile can further stabilize the process, thus improving cycle efficiency. Data shows that manufacturers adopting these techniques can see up to a 30% decrease in scrap rates, leading to significant cost savings and improved productivity in the injection molding process.

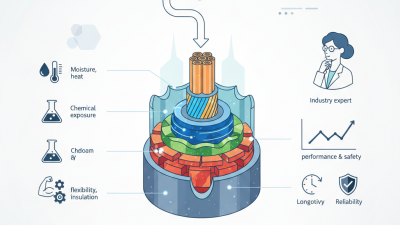

The Importance of Regular Maintenance in Plastic Manufacturing Machinery

Regular maintenance of plastic manufacturing machinery is pivotal to ensuring operational efficiency and product quality. According to a recent report by the American Society of Mechanical Engineers (ASME), nearly 40% of downtime in manufacturing operations can be attributed to equipment failure, with unplanned maintenance being a significant cost factor. The economic implications are profound, as manufacturers lose not only production time but also face the expenses associated with rushed repairs and potential quality assurance issues. Routine inspections and proactive maintenance schedules are essential measures that can mitigate these risks, improving overall efficiency.

Furthermore, the implementation of predictive maintenance strategies can lead to significant improvements in machinery uptime. A 2021 study by the International Journal of Advanced Manufacturing Technology found that applying predictive analytics to machine maintenance can reduce unplanned downtime by up to 30%. This is achieved through data monitoring and analysis, which allows for timely interventions before minor issues escalate into critical failures. Keeping machinery in optimal condition not only enhances productivity but also extends the lifespan of equipment, ultimately leading to cost savings and environmentally sustainable manufacturing practices. Regular maintenance thus plays a crucial role in achieving efficient plastic processing and ensuring the longevity and reliability of production systems.

Top 10 Tips for Efficient Plastic Processing in Manufacturing

This bar chart illustrates the importance level of various tips for efficient plastic processing in manufacturing. Regular maintenance tops the list, emphasizing its critical role in ensuring operational efficiency and reducing downtime.

Effective Waste Management Strategies for Sustainable Plastic Processing

Effective waste management is crucial for sustainable plastic processing in manufacturing. One of the primary strategies involves adopting a circular economy approach, where plastic waste is reintegrated into the production cycle. By implementing processes such as recycling and reengineering used plastics, manufacturers can significantly reduce the amount of waste generated and lower their reliance on virgin materials. Utilizing advanced technologies like sorting systems and granulators can enhance this process, ensuring that plastics are effectively converted back into usable forms.

Additionally, manufacturers should prioritize using biodegradable or recyclable materials in their production lines. Educating employees on waste minimization techniques, such as proper disposal practices and the importance of reducing scrap, can foster a culture of sustainability within the organization. Implementing regular audits to monitor waste levels and identify areas for improvement can also drive efficiency. By focusing on these effective waste management strategies, plastic manufacturers can contribute to environmental sustainability while simultaneously reducing costs and improving their operational efficiency.

Top 10 Tips for Efficient Plastic Processing in Manufacturing - Effective Waste Management Strategies for Sustainable Plastic Processing

| Tip Number | Tip Description | Expected Benefits | Waste Reduction Potential (%) | Implementation Complexity |

|---|---|---|---|---|

| 1 | Optimize Material Selection | Improved product quality and reduced costs | 20 | Low |

| 2 | Implement Recycling Programs | Contributes to circular economy | 30 | Medium |

| 3 | Enhance Process Automation | Increased efficiency and reduced labor costs | 15 | High |

| 4 | Conduct Regular Maintenance | Minimize downtime and extend equipment life | 10 | Low |

| 5 | Train Employees Regularly | Higher efficiency and lower error rates | 18 | Medium |

| 6 | Use Advanced Material Processing Technologies | Enhanced performance and quality | 25 | High |

| 7 | Adopt Life Cycle Assessment (LCA) | Informs sustainable practices and decisions | 22 | Medium |

| 8 | Reduce Cycle Times | Increases throughput and reduces waste | 15 | Medium |

| 9 | Optimize Packaging | Less material use and easier recycling | 28 | Low |

| 10 | Collaborate with Suppliers | Access to sustainable materials and innovations | 20 | Medium |

Related Posts

-

2025 Top Plastic Processing Trends Transforming Manufacturing Innovations

-

Why Choose the Right Cable Compound for Your Electrical Projects?

-

Unlocking the Potential of Filler Masterbatch: Innovations in Polymer Manufacturing

-

2025 Top Compound Cable Types for Enhanced Connectivity Solutions

-

Top 5 Benefits of Using Oxo Biodegradable Products for a Greener Future

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency