- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

What is Color Masterbatch and How is it Used in Plastics?

Color masterbatch plays a crucial role in the plastic industry. It provides vibrant colors and enhances the visual appeal of products. According to industry expert Dr. Emily Harrington, "The right color masterbatch can transform ordinary plastic into a compelling design element." This statement highlights the importance of color in product development.

Manufacturers utilize color masterbatch for various applications. It is designed to be mixed with base polymer during processing. This ensures a uniform distribution of color. However, not all colors meet expectations. Achieving the perfect shade can require several trials. Sometimes, the final product may not match initial visions.

Improper usage of color masterbatch can lead to issues. Color fading or inconsistency can impact a brand’s reputation. Understanding the right concentration and blending techniques is essential. Each batch must be tested for quality assurance. This reflects the ongoing challenge in achieving ideal results in plastic coloration.

What is Color Masterbatch in the Plastics Industry?

Color masterbatch is a crucial component in the plastics industry. It consists of concentrated pigments and additives, pre-dispersed in a resin. This mixture allows manufacturers to achieve specific colors in plastic products efficiently. By using masterbatch, companies can avoid the challenges of directly adding pigments to the material. It simplifies the process and ensures uniform color distribution.

In application, color masterbatch can be used in various plastic products, from packaging to consumer goods. For instance, it can provide vibrant colors for toys or subtle shades for household items. However, the selection of the right masterbatch is vital. Not all masterbatches work well with every type of plastic. Incompatibility can lead to a poor finish or even defects in the product.

Transitions to sustainable options can complicate the decision. Some masterbatches may not comply with environmental standards. Manufacturers need to balance aesthetics, performance, and eco-friendliness, which can be tricky. It's important to continuously reflect on these choices and adapt to emerging trends in the industry.

The Composition and Ingredients of Color Masterbatch

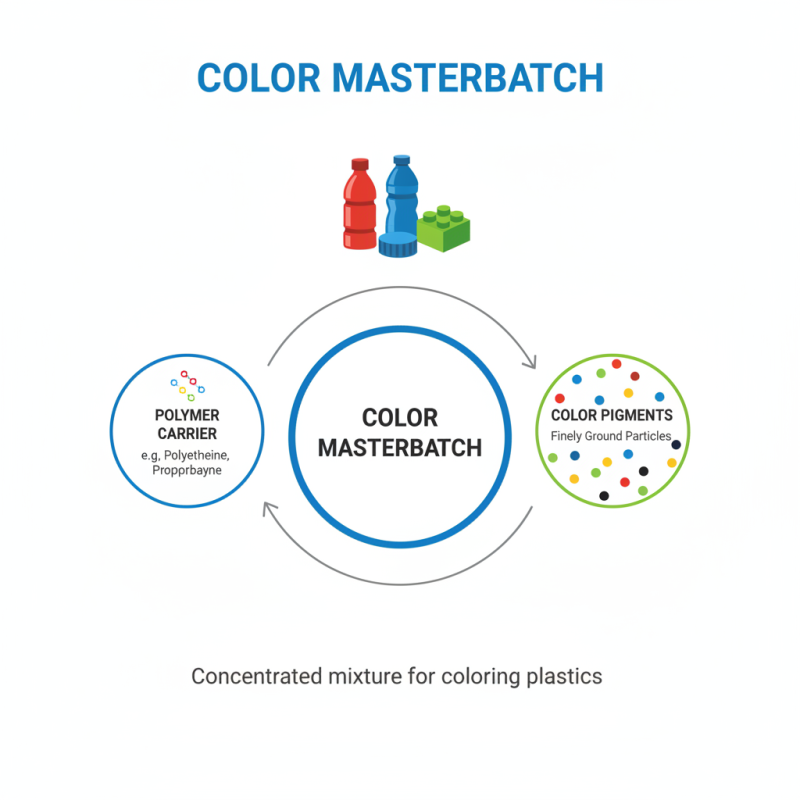

Color masterbatch is a concentrated mixture used for coloring plastics. It comprises a polymer carrier and color pigments. The carrier is usually a polymer like polyethylene or polypropylene. The pigments are finely ground particles that provide color.

These masterbatches are essential for achieving consistent coloration in plastic products. They allow manufacturers to incorporate vibrant colors without compromising the material’s properties. The ratio of pigment to carrier can vary, affecting the final hue and opacity.

**Tip:** Always choose a masterbatch that matches the plastic's processing temperature. Different plastics require different formulations to avoid degradation.

The mixing process involves high shear and heat, ensuring pigments are evenly distributed. However, inconsistencies in temperature can lead to uneven coloring. This requires careful monitoring and adjustments during production.

**Tip:** Conduct small batch tests to verify color before full production. It can save time and resources.

While masterbatches offer great advantages, they can present challenges. Not all pigments are compatible with all plastics. Some may cause issues like discoloration or weak spots. This is an area that often needs more experimentation.

Manufacturing Process of Color Masterbatch for Plastics

The manufacturing process of color masterbatch for plastics involves several key stages. Initially, a polymer carrier is selected based on the final application. Common carriers include polypropylene and polyethylene. This choice impacts the final product’s compatibility and performance. According to industry reports, the global color masterbatch market was valued at approximately $3.4 billion in 2021, and it is expected to grow significantly.

After selecting the polymer, pigments and additives are mixed. The pigment concentration typically ranges from 20% to 70%. Achieving a uniform dispersion is critical. If the mixing is insufficient, color consistency may suffer. Manufacturers often use high-shear mixers for better results. However, the process can vary. Some producers still rely on traditional methods, which may lead to uneven color quality.

The next stage involves extrusion. The mixture is heated and forced through a die. This step creates pellets or granules, ready for further processing. Cooling is crucial to ensure the final shape is maintained. Reports indicate that operational inefficiencies during this phase can increase production costs. Additionally, the consistency of the final product should be monitored closely, as variations can occur, impacting the plastic’s appearance. Quality control is essential throughout the process, yet it can be challenging.

Color Masterbatch Usage in Plastics by Industry

Applications of Color Masterbatch in Various Plastic Products

Color masterbatch is widely used in plastic products, providing vibrant colors and effects. These concentrated colorants come in pellet form and are easy to blend. Commonly, manufacturers incorporate color masterbatch during the extrusion and injection molding processes. This allows for consistent color distribution throughout the product, enhancing visual appeal.

Applications of color masterbatch span various industries. For example, packaging often utilizes bright colors to attract consumers. It can be found in food containers, bottles, and shopping bags. Additionally, color masterbatch is essential in the automotive industry, where it is used for interior components and exterior finishes. The right shade can influence customer perception, yet sometimes the choices may not resonate with all.

Moreover, the use of color masterbatch in household items such as toys and furniture can face challenges. Colors may fade over time due to UV exposure. It raises questions about durability and whether manufacturers should consider alternative solutions. The quest for the perfect color is ongoing, highlighting a need for innovation and reflection on consumer preferences.

What is Color Masterbatch and How is it Used in Plastics? - Applications of Color Masterbatch in Various Plastic Products

| Application | Plastic Type | Color Masterbatch Type | Typical Usage |

|---|---|---|---|

| Packaging | Polyethylene (PE) | Masterbatch with High Color Concentration | Food Packaging Bags |

| Automotive | Polypropylene (PP) | UV-Stabilized Masterbatch | Interior and Exterior Trim |

| Consumer Goods | ABS Plastic | Matte Finish Masterbatch | Household Appliances |

| Construction | Polyvinyl Chloride (PVC) | Weather-Resistant Masterbatch | Pipes and Fittings |

| Electronics | Polycarbonate (PC) | Flame Retardant Masterbatch | Covers and Housings |

Advantages of Using Color Masterbatch in Plastic Production

Color masterbatch is a concentrated mixture of pigments and additives in a carrier resin. This product is pivotal in the plastics industry. It allows manufacturers to produce vibrant colors efficiently. Using color masterbatch boosts production speed. The incorporation is straightforward and versatile.

One significant advantage of color masterbatch is its consistency. It ensures that colors remain uniform across batches. This is crucial for maintaining the quality of final products. It minimizes color variations and waste. It can be easy to overlook the importance of color consistency until discrepancies arise.

Tips: Always test small samples first. This will help ensure the desired hue matches your expectations. While masterbatches enhance efficiency, poor mixing can lead to unexpected shades. Be mindful of the loading levels; too much can sometimes muddy the intended color.

Related Posts

-

How to Choose the Right Color Masterbatch for Your Plastic Products?

-

2025 Top Trends in Color Masterbatch for Sustainable Plastic Solutions

-

What is Color Masterbatch and How It Transforms Plastic Manufacturing

-

Unlocking Creative Potential: How Color Master Batches Transform Plastic Manufacturing

-

How to Choose the Right Plastic Color Masterbatch for Your Projects

-

Top 5 Surya Masterbatch Products to Boost Your Plastic Manufacturing Efficiency