- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

How to Choose the Right Black Masterbatch for Your Plastic Applications

In the plastic manufacturing industry, the selection of appropriate additives is crucial for achieving the desired aesthetic and functional properties. Among these additives, black masterbatch has emerged as a key player, driving advancements in color and performance for various applications. According to a recent market research report by Grand View Research, the global masterbatch market was valued at approximately USD 12 billion in 2021, with black masterbatch representing a significant segment due to its versatility and ability to enhance both visual appeal and mechanical properties of plastics.

The importance of choosing the right black masterbatch cannot be overstated. It influences the opacity, tint strength, and thermal stability of the end product. As highlighted in a 2022 study by Research and Markets, the demand for environmentally friendly and high-performance black masterbatch solutions is on the rise, projected to grow at a compound annual growth rate (CAGR) of 5.4% through the next five years. This surge in demand necessitates an informed approach to selection to meet specific requirements for performance, compatibility, and sustainability in diverse plastic applications.

Understanding the core aspects of black masterbatch—including its composition, application scenarios, and regulatory compliance—can empower manufacturers to make informed decisions. Thus, a critical assessment of parameters such as loading levels, carrier resin compatibility, and additive features is necessary to achieve optimal results in performance and cost-efficiency.

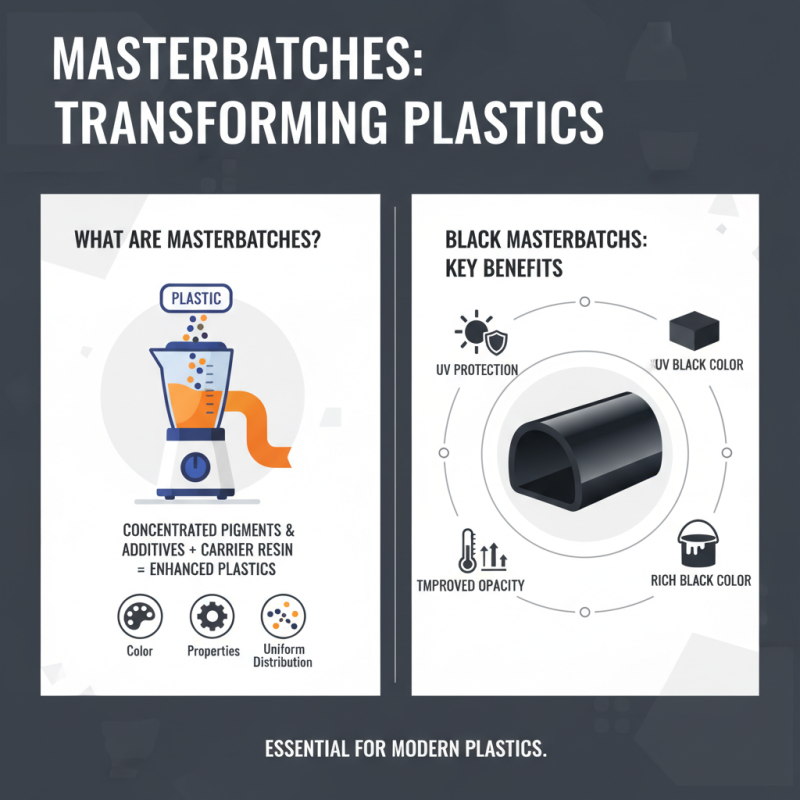

Understanding Masterbatches and Their Role in Plastics

Masterbatches are concentrated mixtures of pigments and additives encapsulated in a carrier resin, designed to enhance the properties of plastics. They serve a crucial role in the manufacturing process by allowing for uniform distribution of color and performance-enhancing properties in plastic products. Black masterbatches, in particular, are essential for achieving deep, rich black hues in the final product while also providing benefits such as UV protection, thermal stability, and improved opacity.

When selecting the right black masterbatch for specific plastic applications, several factors must be considered. The type of polymer, the processing methods, and the desired end-use characteristics play a significant role in the selection process. Compatibility between the masterbatch and the base resin is vital, as well as the concentration level, which affects color intensity and overall performance. Additionally, understanding the processing conditions such as temperature and shear rates can help determine the right formulation to ensure optimal dispersion and consistency throughout the plastic matrix.

Types of Black Masterbatch Available in the Market

When selecting the right black masterbatch for your plastic applications, understanding the types available in the market is crucial. Black masterbatch can be categorized into several types based on their formulation and intended use. The most common types include carbon black masterbatch, which offers excellent UV protection and color stability, and pigment-based masterbatch, which can produce a deeper, more uniform black finish. Additionally, there are carrier types that determine how well the masterbatch integrates with different polymer hosts, including polyethylene and polypropylene.

When choosing a black masterbatch, it's essential to consider specific application requirements. Here are some tips: Firstly, assess the required shade and finish. Different black masterbatches can yield variations in tone and glossiness, making it important to match these attributes with your product design. Secondly, evaluate the processing conditions to ensure compatibility with your manufacturing methods. Not all black masterbatches are suited for every processing technology, so conducting pre-tests can save time and resources. Lastly, factor in the end-use environment; for outdoor applications, selecting a masterbatch with UV stabilization features can enhance longevity and performance.

Understanding these key factors when selecting a black masterbatch will help you achieve the desired quality and functionality in your plastic products.

Types of Black Masterbatch Available in the Market

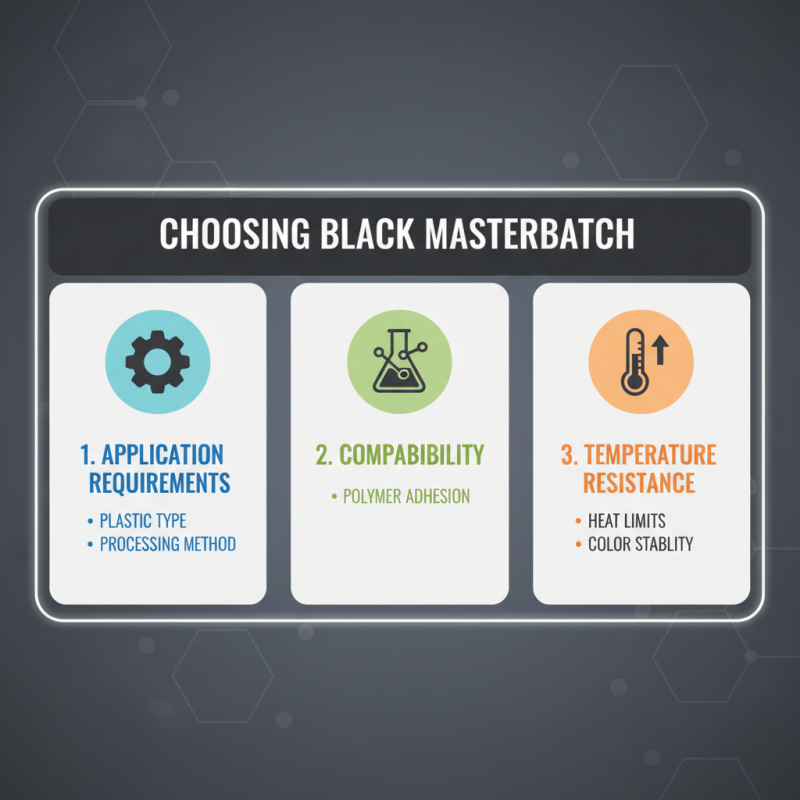

Key Factors to Consider When Choosing Black Masterbatch

When choosing the right black masterbatch for your plastic applications, several key factors should be taken into consideration to ensure optimal results. Firstly, it's crucial to assess the application requirements such as the type of plastic, processing methods, and end-use conditions. Different plastics may react uniquely with specific types of colorants, so understanding the compatibility of black masterbatch with your chosen polymer is essential. Additionally, consider the processing temperature and limits; some masterbatches can withstand higher heat while retaining their color integrity, which is vital for applications involving high processing temperatures.

Another important factor is the desired shade and concentration of black. Different formulations can achieve various levels of opacity and depth of color, so it’s essential to determine the right concentration that achieves the intended aesthetic without compromising other physical properties of the finished product. Evaluating the UV resistance and lightfastness of the masterbatch is also crucial, especially for applications exposed to sunlight, as these characteristics impact the longevity and durability of the color. Ultimately, the correct selection of black masterbatch will enhance product quality and performance, resulting in a successful application tailored to specific needs.

Evaluating Performance and Compatibility of Masterbatches

When selecting the right black masterbatch for plastic applications, evaluating performance and compatibility is essential to ensure the final product meets quality standards. Masterbatches are concentrated mixtures of pigments and additives that are combined with a polymer to produce colored plastics. According to a report by Smithers Pira in 2022, the global masterbatch market is projected to reach $16 billion by 2027, indicating a significant growth trend driven by the need for high-performance plastic materials. Factors such as dispersion quality, color strength, and melt flow index significantly influence the compatibility of black masterbatch with various polymers, including polyethylene, polypropylene, and polystyrene.

Tips for evaluating masterbatch performance include conducting thorough compatibility tests with the base resin. This can be achieved through techniques like melt flow rate testing and color matching assessments, which may reveal how well the masterbatch integrates with the polymer matrix. Additionally, consider the UV stability and thermal resistance of the masterbatch to ensure it can withstand the conditions of the intended application. A comprehensive understanding of the end-use environment will help make an informed decision, especially as industries push for more sustainable solutions.

Another important consideration is the regulatory compliance of the masterbatch formulation, particularly in food contact applications. Implementing rigorous testing protocols, such as migration studies, can help ensure that the chosen black masterbatch does not adversely affect the safety or performance of the final plastic product. By prioritizing these evaluations, manufacturers can enhance product reliability while meeting consumer and regulatory standards effectively.

Cost Efficiency and Environmental Impact of Black Masterbatch Choices

When selecting a black masterbatch for plastic applications, cost efficiency and environmental impact are crucial factors to consider. The choice of masterbatch significantly affects the overall material costs, as it contributes to both the raw material expenses and the processing costs in production. A high-quality black masterbatch may require a greater initial investment, but it often results in reduced material use over time due to its superior pigmentation and performance, leading to less wastage and improved durability of the final product.

In addition to cost considerations, the environmental impact is increasingly becoming a priority for manufacturers. Sustainable black masterbatch options are available that utilize recycled materials or bio-based components, aligning with eco-friendly practices. These alternatives not only minimize the carbon footprint but can also enhance brand reputation in a market that values sustainability. Evaluating the life cycle of the chosen masterbatch, from raw material sourcing to end-of-life disposal, can provide insights into its long-term environmental implications, allowing businesses to make informed decisions that balance cost efficiency with ecological responsibility.

Related Posts

-

Top 5 Benefits of Using Oxo Biodegradable Products for a Greener Future

-

Exploring the Future of EVA Masterbatch: Trends and Innovations in Polymer Additives for 2024

-

Exploring the Fascinating World of Plastic Effects: How They Transform Our Everyday Materials

-

Unlocking the Potential of Filler Masterbatch: Innovations in Polymer Manufacturing

-

What is a Compound Cable and How Does It Improve Electrical Connections

-

Exploring the Benefits of Using White Masterbatch in Sustainable Plastic Production