- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

How to Choose the Right Plastic Color Masterbatch for Your Projects

Choosing the right plastic color masterbatch for your projects is a crucial decision that can significantly impact both the aesthetics and functionality of your end products. With an array of options available in the market, understanding the characteristics of different masterbatches is essential for achieving your desired outcomes. Whether you are working on packaging materials, automotive components, or household items, the right color masterbatch can enhance not only the visual appeal but also the performance attributes of the plastic.

In this guide, we will explore the key factors to consider when selecting a plastic color masterbatch. From the type of resin you are using to the specific effects you wish to achieve, each element plays a vital role in ensuring that your project meets both industry standards and consumer expectations. Additionally, we will delve into aspects such as compatibility, concentration levels, and the environmental impact of the color masterbatch you choose, providing you with the knowledge necessary to make informed decisions that align with your project's goals.

Factors to Consider When Selecting Color Masterbatch for Plastics

When selecting the right plastic color masterbatch for your projects, there are several critical factors to consider to ensure that your final product meets aesthetic and functional requirements. First, evaluate the specific application of your plastic product. Different applications may require unique properties, including UV resistance, weathering stability, or compliance with regulatory standards. Understanding the end-use of your product will guide you in selecting a masterbatch that adds value while preserving performance.

Another key consideration is the compatibility of the masterbatch with the selected resin. It’s essential to choose a color masterbatch that is formulated to work well with the type of plastic you are using, whether it's polypropylene, polyethylene, or another polymer. Compatibility affects not only the color quality but also how well the masterbatch disperses within the resin, which can impact processing and final appearance.

**Tips:** Always request samples and conduct tests to ensure optimal dispersion and color matching. Additionally, consider the environmental impact of your choice.Opt for masterbatches that are made from environmentally friendly colorants whenever possible, to contribute to sustainability in your projects. Finally, keep in mind the cost-effectiveness of the chosen masterbatch without compromising on quality. Balancing these factors will lead to the best results in your plastic color projects.

Understanding Different Types of Plastic Color Masterbatches Available

When choosing the right plastic color masterbatch for your projects, it's crucial to understand the various types available in the market.

Plastic color masterbatches can be broadly categorized into two main types:

standard and customized.

Standard masterbatches typically consist of universal colors that can be used across numerous applications, making them cost-effective and readily available.

Reports indicate that the global masterbatch market is projected to grow at a CAGR of 5.2% from 2021 to 2028, signaling an increasing demand for efficient and versatile color solutions in plastic manufacturing.

Customized masterbatches, on the other hand, offer tailored solutions aimed at meeting specific project requirements.

These can involve unique colors, effects, or characteristics and are particularly beneficial for niche applications where standard options may not suffice.

According to industry insights, the demand for customized masterbatches is rising as manufacturers seek differentiation in a competitive environment.

Factors such as the growing emphasis on aesthetics in product design and advances in color technology are driving this trend, with customization providing manufacturers the flexibility to innovate and align with consumer preferences.

By understanding these differences, businesses can make informed decisions that enhance the effectiveness and appeal of their plastic products.

Impact of Pigment Concentration on Color Quality and Plastic Properties

When selecting a plastic color masterbatch, one of the critical factors to consider is the pigment concentration, which significantly influences both the color quality and the overall properties of the final plastic product. A higher pigment concentration generally leads to more vibrant and intense colors; however, it can also affect the physical attributes of the polymer. For example, higher levels of pigment can increase the opacity of the material, making it more suitable for applications requiring low light transmission. Conversely, if the concentration is too high, it may result in processing challenges, such as increased viscosity or issues with dispersibility.

On the other hand, a lower pigment concentration might lead to a more translucent appearance, which may be desirable for specific applications where light diffusion is essential. However, this trade-off often results in a less saturated color, potentially affecting the aesthetic appeal of the finished product. Moreover, the choice of pigments and their interaction with the plastic matrix can alter mechanical properties, such as impact resistance and rigidity. Therefore, it is crucial for manufacturers to strike a careful balance when selecting the right pigment concentration in color masterbatches to achieve the desired aesthetic as well as functional characteristics in their plastic products.

Impact of Pigment Concentration on Color Quality and Plastic Properties

This chart illustrates the impact of different pigment concentrations on color quality and plastic properties for various projects.

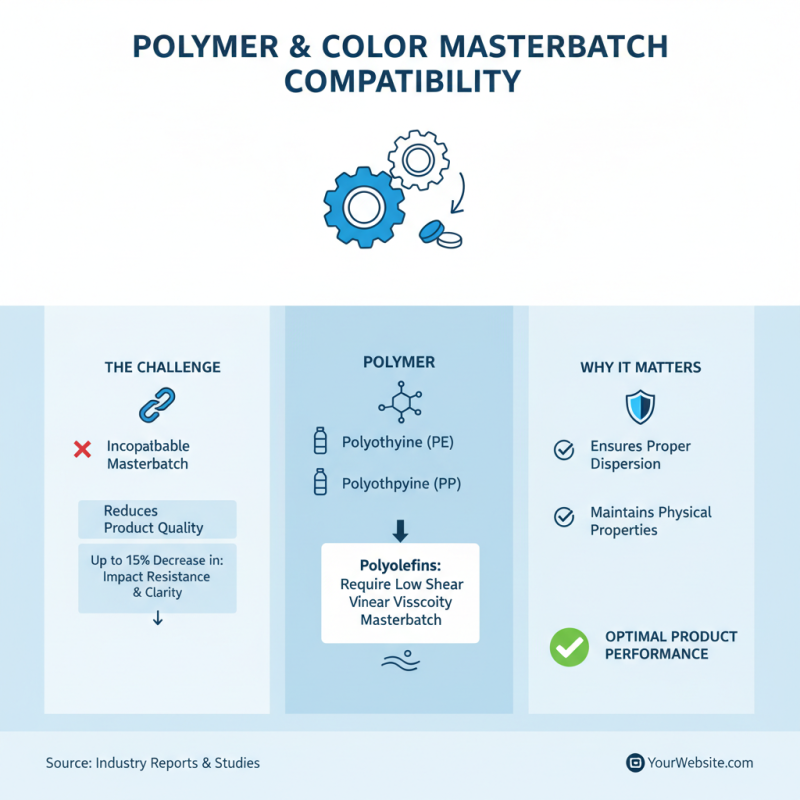

Evaluating Compatibility of Masterbatch with Base Polymers Used

When selecting the right plastic color masterbatch, evaluating its compatibility with the base polymers used in your projects is critical. Different polymers have unique properties that can influence how they interact with the color masterbatch. For instance, polyolefin-based polymers, such as polyethylene and polypropylene, often require masterbatches with low shear viscosity to ensure proper dispersion and coloring without affecting the physical properties of the final product. Industry reports indicate that improper selection can lead to a decrease in impact resistance and clarity, with some studies showing that incompatible masterbatches can reduce product quality by up to 15%.

Tips for assessing compatibility include conducting preliminary tests with small batches, assessing color dispersion and stability under processing conditions, and reviewing the masterbatch supplier's technical data sheets for polymer-specific formulations. For example, when working with polystyrene, it is advisable to choose masterbatches specifically designed to align with its processing temperatures and shear rates, as this ensures better integration and performance.

Additionally, it's essential to consider the intended application of the final product. For medical or food packaging applications, the compatibility of masterbatch with polymers can also affect regulatory compliance. Research has shown that specific colorants used in masterbatches can migrate into food products, hence understanding these interactions is pivotal for both safety and performance. Always consult material safety data sheets and invest time in compatibility studies to avoid costly production issues down the line.

Sustainability and Environmental Considerations in Color Masterbatch Selection

When selecting a plastic color masterbatch for your projects, sustainability and environmental considerations play a critical role in the decision-making process. With increasing awareness of environmental issues, manufacturers are tasked with not only creating products that meet aesthetic demands but also aligning with eco-friendly practices. Choosing color masterbatches that are produced using sustainable methods can significantly reduce your project's carbon footprint. For instance, opting for formulations that utilize renewable resources or recycled materials can contribute to a more circular economy.

Moreover, the biodegradability and recyclability of color masterbatches should be taken into account. Many companies are now developing masterbatches that can decompose naturally or integrate seamlessly into recycling streams. This not only lessens the impact on landfills but also enhances the marketability of products made with these materials. Furthermore, ensuring that the selected color masterbatches adhere to environmental regulations and standards ensures that your projects are not only visually appealing but also responsible, appealing to a growing consumer base that prioritizes sustainability in their purchasing decisions.

How to Choose the Right Plastic Color Masterbatch for Your Projects - Sustainability and Environmental Considerations in Color Masterbatch Selection

| Masterbatch Type | Pigment Type | Sustainability Rating | Recyclability | Applications |

|---|---|---|---|---|

| Standard Color Masterbatch | Organic Pigments | Medium | Yes | Packaging, Toys |

| Eco-Friendly Masterbatch | Natural Dyes | High | Yes | Consumer Goods, Housewares |

| Recycled Masterbatch | Reclaimed Pigments | Very High | Yes | Building Materials, Automotive |

| UV Stabilized Masterbatch | Inorganic Pigments | Medium | No | Outdoor Products, Furniture |

| Glow-in-the-Dark Masterbatch | Phosphorescent Pigments | Low | No | Toys, Safety Equipment |

Related Posts

-

What is Color Masterbatch and How It Transforms Plastic Manufacturing

-

Top 5 Surya Masterbatch Products to Boost Your Plastic Manufacturing Efficiency

-

2025's Top 10 Plastic Filler Masterbatch Innovations for Enhanced Performance

-

2025 Guide: How to Choose the Right Compound Filler for Your Projects

-

Top 5 Benefits of Using Oxo Biodegradable Products for a Greener Future

-

10 Essential Tips for Choosing the Right Polyethylene Masterbatch for Your Projects