- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

Why Choose the Right Cable Compound for Your Electrical Projects?

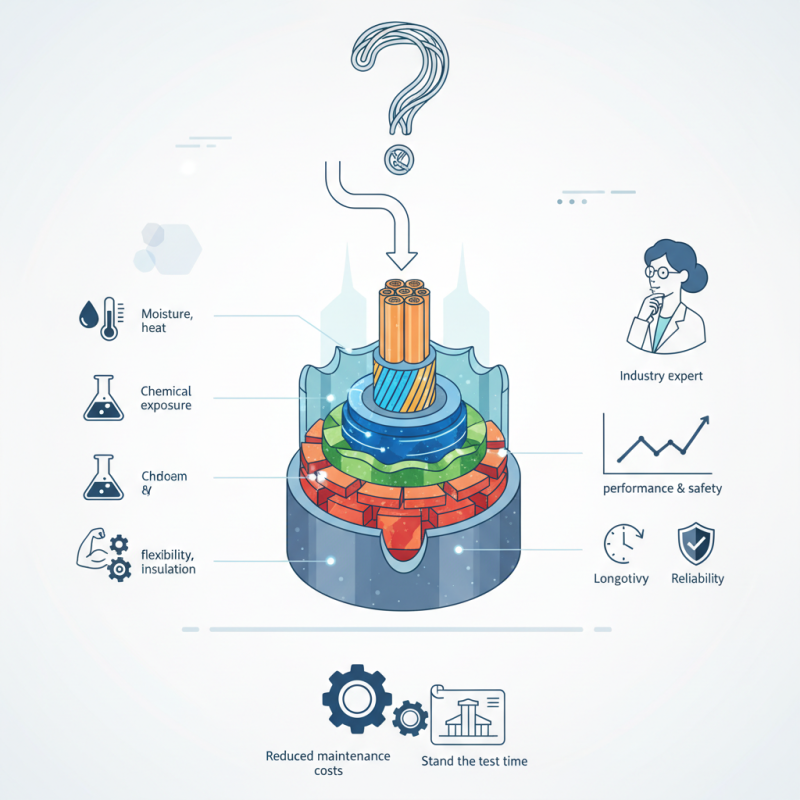

Choosing the right cable compound for your electrical projects is a critical decision that can significantly impact both performance and safety. As the industry continues to evolve, understanding the properties and applications of various cable compounds becomes essential. According to Dr. Emily Carter, a renowned expert in the field of electrical materials, “The correct cable compound not only determines the longevity of the cable but also ensures its reliability under different environmental conditions.” This emphasizes the importance of selection in achieving optimal results.

The cable compound acts as a protective layer, shielding the electrical components from environmental factors such as moisture, heat, and chemical exposure. Therefore, it is crucial to consider the specific requirements of your project—including temperature ranges, flexibility, and insulation properties—when choosing a cable compound. By doing so, you can mitigate the risks of premature failure and enhance the overall efficacy of your electrical systems.

In conclusion, making an informed decision about cable compounds is vital for any electrical project. The insights from industry experts like Dr. Carter highlight the significance of understanding the materials at play and their implications for safety and longevity. Selecting the right cable compound can ultimately lead to improved performance and reduced maintenance costs, ensuring that your projects stand the test of time.

Understanding the Role of Cable Compounds in Electrical Projects

Cable compounds play a critical role in the performance and safety of electrical projects. These materials are designed to provide insulation, protection, and support for electrical conductors, ensuring that they operate effectively under a variety of conditions. The choice of cable compound can significantly impact the overall efficiency and longevity of electrical systems. For instance, compounds that offer superior thermal stability can prevent overheating, while those with high chemical resistance can safeguard cables from harsh environmental factors.

Furthermore, the right cable compound contributes to the reduction of electrical losses, improving energy efficiency in systems. Different applications may require specific properties, such as flexibility for installations in confined spaces or increased tensile strength for harsh environments. Understanding the unique requirements of each project allows engineers and electricians to select the most suitable cable compound, leading to enhanced performance and reliability. Ultimately, a thorough comprehension of cable compounds is essential to optimizing electrical installations and ensuring they meet safety standards and operational expectations.

Why Choose the Right Cable Compound for Your Electrical Projects?

This chart illustrates the importance of different cable compounds in electrical projects, focusing on their performance characteristics such as thermal stability, flexibility, and resistance to chemicals.

Types of Cable Compounds and Their Unique Properties

When selecting a cable compound for electrical projects, different types possess unique properties that can significantly influence performance and durability. For instance, thermoplastic elastomers (TPEs) are renowned for their excellent flexibility and resistance to high temperatures, making them an optimal choice for applications that require movement and exposure to heat. According to a 2022 market analysis by the Plastics Industry Association, the demand for TPEs in electrical insulation has increased by over 15% annually due to their superior tensile strength and elongation properties.

Conversely, cross-linked polyethylene (XLPE) is favored for its exceptional resistance to chemicals and moisture, which is critical in underground or industrial applications. A report by the International Energy Agency notes that XLPE cables can sustain high voltage levels and have a lifespan that exceeds 40 years when properly installed. Furthermore, the choice of cable compound can also influence fire safety; compounds that incorporate flame-retardant additives are essential in residential and commercial buildings where safety regulations mandate strict compliance with fire safety standards. The National Fire Protection Association (NFPA) highlights that the right materials can reduce the spread of flames by up to 70%.

Selecting the appropriate cable compound is paramount for ensuring the reliability and efficiency of electrical systems, as each compound's distinct characteristics can profoundly impact overall project success.

Factors to Consider When Selecting Cable Compounds

When selecting the right cable compounds for electrical projects, several critical factors come into play.

The first consideration is the environmental conditions in which the cables will operate.

Factors such as temperature extremes, exposure to moisture, and the presence of chemicals

can all influence the durability and performance of the cable. Choosing a compound that offers

excellent thermal stability and resistance to environmental stressors ensures

a longer lifespan and reduced maintenance costs.

Another essential factor is electrical performance, which includes

insulation resistance and dielectric strength. These properties are vital for preventing electrical failures

and ensuring safety in installations. Additionally, fire resistance is a key characteristic to look for,

particularly in commercial or industrial settings where safety regulations may require compliance to

specific fire standards.

The Impact of Cable Compounds on Performance and Longevity

The choice of cable compound plays a crucial role in the overall performance and longevity of electrical projects. Different environments and applications demand specific properties from cable compounds, such as thermal resistance, flexibility, and chemical durability. For instance, compounds designed for outdoor use often incorporate UV inhibitors and enhanced moisture resistance to withstand harsh weather conditions. In contrast, compounds for indoor applications may prioritize low smoke and toxicity in the event of a fire, ensuring safety and compliance with building codes.

Moreover, the longevity of electrical cables is significantly influenced by the selection of the right compound. High-quality materials can prevent degradation over time, maintaining electrical efficiency and reducing maintenance costs. For example, compounds that resist abrasion and tearing can prolong the life of cables installed in high-traffic areas or industrial settings. As a result, investing time in selecting the appropriate cable compound is essential, as it directly impacts the reliability of electrical systems and the overall success of any project.

Why Choose the Right Cable Compound for Your Electrical Projects? - The Impact of Cable Compounds on Performance and Longevity

| Cable Compound Type | Temperature Range (°C) | Flexibility | UV Resistance | Longevity (Years) |

|---|---|---|---|---|

| PVC (Polyvinyl Chloride) | -15 to 60 | Moderate | Low | 10 |

| XLPE (Cross-Linked Polyethylene) | -40 to 90 | High | High | 30 |

| PE (Polyethylene) | -40 to 60 | High | Moderate | 20 |

| Rubber | -40 to 90 | Very High | High | 15 |

| TSN (Thermoplastic Elastomer) | -50 to 90 | Very High | Very High | 25 |

Common Applications and Recommendations for Cable Compounds

When selecting the right cable compound for electrical projects, understanding common applications is essential. Cable compounds are primarily categorized based on their thermal and electrical properties, and their resistance to environmental stressors.

For instance, in outdoor applications where exposure to moisture, UV light, and temperature fluctuations is a concern, compounds like polyvinyl chloride (PVC) or cross-linked polyethylene (XLPE) are widely utilized. These materials offer excellent durability and protection, ensuring longevity and performance in harsh conditions.

For instance, in outdoor applications where exposure to moisture, UV light, and temperature fluctuations is a concern, compounds like polyvinyl chloride (PVC) or cross-linked polyethylene (XLPE) are widely utilized. These materials offer excellent durability and protection, ensuring longevity and performance in harsh conditions.

In contrast, for indoor applications, particularly in areas requiring flexibility and ease of installation, thermoplastic elastomers (TPE) or thermoplastic polyurethane (TPU) are often recommended. These compounds provide a balance between flexibility and strength, making them ideal for use in tight spaces or where cables may be subject to bending. Moreover, considerations such as fire resistance and low smoke emissions become crucial in residential or commercial buildings, where safety standards are paramount. By carefully assessing the specific needs of each project, choosing the appropriate cable compound can enhance both functionality and safety.

Related Posts

-

2025's Top 10 Plastic Filler Masterbatch Innovations for Enhanced Performance

-

Exploring the Benefits of Using White Masterbatch in Sustainable Plastic Production

-

Revolutionizing Repair: Understanding the Science Behind Plastic Fillers and Their Environmental Impact

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency

-

Top 10 Biodegradable Masterbatch Options for Sustainable Packaging Solutions

-

2025 Top Compound Cable Types for Enhanced Connectivity Solutions