- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

How to Choose the Right Plastik Masterbatch for Your Needs?

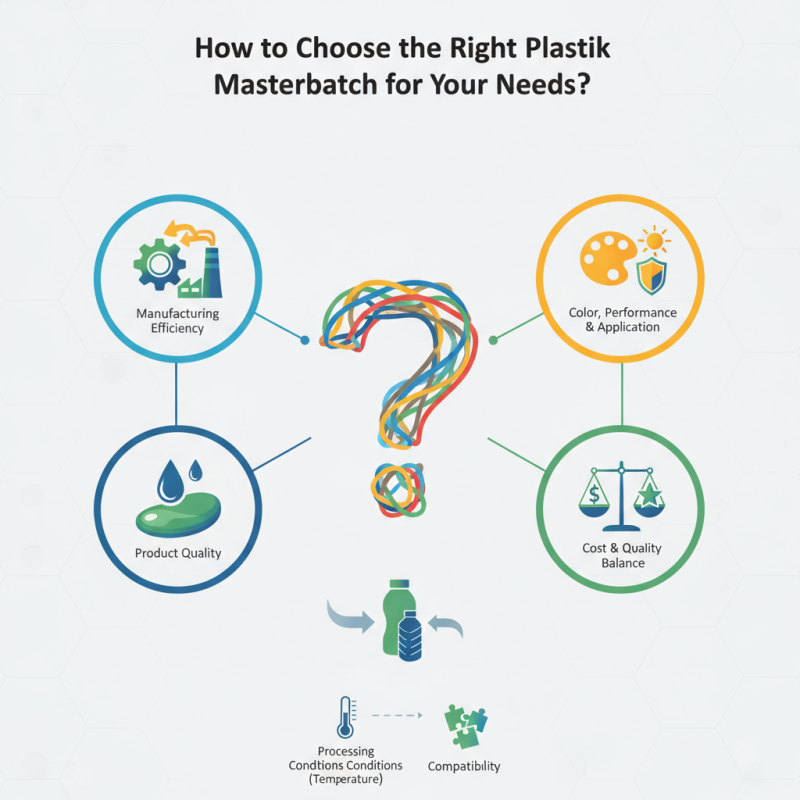

Choosing the right plastik masterbatch is crucial for manufacturing efficiency and product quality. Many factors come into play during this selection process. Understanding your specific needs is essential.

Plastik masterbatch products vary in color, performance, and application. They can significantly affect the final product's appearance and functionality. Selecting the wrong type may lead to poor results or wasted resources. One must consider the intended use of the plastic, along with processing conditions like temperature and compatibility.

When deciding, evaluate your project's unique requirements. Are you looking for vibrant colors, UV protection, or durability? Many options exist, but not all will suit your purposes perfectly. Reflecting on past choices can guide current decisions. Balancing cost and quality is often challenging, but crucial for success.

Understanding the Basics of Plastik Masterbatch and Its Applications

Plastik masterbatch is a concentrated mixture of additives that enhance the performance of plastic products. Understanding its applications is crucial for various industries. For instance, in the packaging sector, masterbatch can improve clarity, strength, and color of films. The global plastic masterbatch market is projected to reach approximately $14 billion by 2027, according to a report by Fortune Business Insights. Companies must consider the specific requirements of their applications when selecting the right masterbatch.

Different types of masterbatches serve varied purposes. Color masterbatches are used to achieve specific hues, while additive masterbatches may include UV stabilizers or anti-static agents. These functionalities are essential for meeting industry standards and enhancing product lifespan. However, the increase in variety can lead to confusion. Not all options may work effectively for every application, and testing is often necessary.

Additionally, environmental concerns have shifted the focus toward sustainable options. Biodegradable masterbatches gain popularity but may not perform equally. A study highlighted that up to 30% of companies reported challenges with consistency in biodegradable materials. Identifying the right balance between performance and sustainability requires careful evaluation. Selecting the wrong type can lead to production delays and increased waste. Therefore, it's essential to assess needs thoroughly before making a choice.

Understanding the Different Types of Plastik Masterbatch and Their Applications

Identifying Your Specific Needs and Requirements for Masterbatch

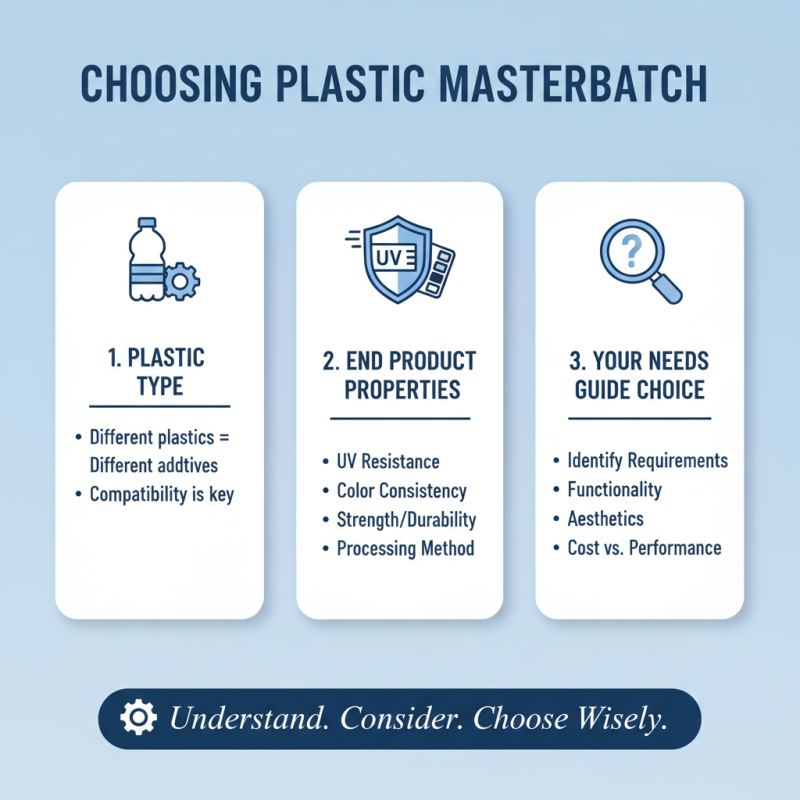

Choosing the right plastic masterbatch starts with understanding your needs. Think about the type of plastic you use. Different plastics require different additives. Consider the end product’s properties. Do you need UV resistance? Or perhaps color consistency? Each need will guide your choice.

Evaluate the specific application of the masterbatch. Will it be used in high-temperature environments? If so, thermal stability becomes crucial. If you're focusing on aesthetics, the pigment concentration is key. Test samples when possible. This helps identify if a product truly meets your expectations. Sometimes, initial trials can be misleading.

Don't overlook cost-effectiveness. While it’s tempting to opt for cheaper options, they may lack quality. Poor performance can lead to rework and wasted materials. Reflect on your priorities. Balancing quality and cost is often challenging but necessary. Keeping these factors in mind can streamline your selection process.

Evaluating the Types of Plastik Masterbatch Available in the Market

When it comes to selecting the right plastik masterbatch, understanding the options available is crucial. There are various types in the market, each suited for different applications. For instance, color masterbatches are commonly used to impart vibrant colors to plastic products. On the other hand, additive masterbatches enhance the properties of materials, such as UV resistance or flame retardancy. Evaluating your specific needs will help narrow down the choices.

Consider the application of the plastik masterbatch. Some products require greater flexibility, while others might need durability. In addition, you could also think about the desired finish—glossy or matte? The selection process can feel overwhelming at times. Sometimes, products may not perform as expected due to unforeseen factors. Testing samples before committing to a bulk purchase can be an effective strategy. It's vital to reflect on your production processes and anticipate potential challenges that could arise during implementation.

Key Factors to Consider When Choosing Plastik Masterbatch

Choosing the right plastik masterbatch requires careful consideration of several key factors. The type of plastic you are working with is crucial. Different plastics can react uniquely to various masterbatch formulations. For example, a polyethylene-based plastic may not perform well with a masterbatch designed for polystyrene. Testing is essential.

Color is another important detail. The shade you choose must meet your design and branding needs. It's wise to request samples before making a bulk purchase. The quality of the pigments can vary, potentially impacting the final product's appearance. A vibrant color from one supplier may look dull from another.

Tips: Always check for compatibility. Look for data sheets and technical specifications. Ensure you understand how the masterbatch will behave during processing. Explore pricing but also prioritize quality. Remember, you get what you pay for.

Consider the environmental impact of your choice. Some masterbatches are more sustainable than others. In today's market, eco-friendly options can enhance your brand image. Don't only chase cost savings; think about long-term implications. Low-quality products can lead to waste and inefficiencies.

Testing and Compatibility: Ensuring the Right Fit for Your Production Process

Choosing the right plastic masterbatch requires careful attention. Compatibility is crucial for a smooth production process. Testing the materials beforehand is a smart move. Different polymers interact uniquely with various additives. A mismatch can lead to issues like poor dispersion or unexpected reactions.

Conducting compatibility tests in small batches can save time and resources. Observe the color consistency and processing behavior. Sometimes, even slight deviations can alter product quality. It’s essential to document these tests thoroughly. Reflection on past experiences helps in making informed choices.

Understanding the specific requirements of your production line can streamline the selection process. Variables like temperature and shear rates matter. Overlooking these can lead to unanticipated challenges. Evaluate all factors before making a decision. A well-thought-out selection can enhance efficiency and product performance.

How to Choose the Right Plastik Masterbatch for Your Needs?

| Property | Description | Testing Method | Compatibility |

|---|---|---|---|

| Color Consistency | Uniform color throughout the product. | Visual Inspection / Spectrophotometry | Polyethylene and Polypropylene |

| Melt Flow Index (MFI) | Measure of the polymer's viscosity. | Melt Flow Index Tester | Nylon compatibile |

| Opacity | Ability to block light transmission. | Haze Meter | Compatible with ABS |

| Thermal Stability | Ability to maintain properties under heat. | Thermogravimetric Analysis | PVC compatible |

| UV Resistance | Resistance to degradation from UV light. | Xenon Arc Test | Suitable for outdoor products |

Related Posts

-

Exploring the Benefits of Compound Masterbatch: Industry Trends and Performance Metrics for 2024

-

Top 10 Benefits of Using Compound Masterbatch in Plastics Manufacturing

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency

-

2026 Best Slip Masterbatch Options for Enhanced Performance and Efficiency?

-

Top 5 Surya Masterbatch Products to Boost Your Plastic Manufacturing Efficiency

-

Unlocking the Benefits of Anti Block Masterbatch: Revolutionizing Plastics with Enhanced Performance