- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

Top 10 Biodegradable Masterbatch Options for Sustainable Packaging Solutions

As the world increasingly shifts towards

sustainable practices, the packaging industry

is undergoing a transformation focused on reducing environmental impact. Among the

innovative solutions making waves in this sector, biodegradable masterbatch options

stand out as a promising alternative to traditional plastic materials. These masterbatches

not only enhance the properties of packaging films and products but also ensure that they

can decompose naturally, mitigating the long-lasting effects of plastic waste on our planet.

The quest for eco-friendly packaging has never been more critical, with consumers and

businesses alike seeking ways to minimize their carbon footprint. Biodegradable masterbatch

serves as a vital component in this movement, allowing manufacturers to create products that

align with sustainability goals without compromising on performance. In this article, we will

explore the top 10 biodegradable masterbatch options available in the market today,

highlighting their unique features, applications, and benefits for sustainable packaging solutions.

By understanding these options, companies can make informed decisions that not only protect

our environment but also resonate with the growing demand for responsible and green

packaging alternatives.

Introduction to Biodegradable Masterbatch in Sustainable Packaging

Biodegradable masterbatch has emerged as a key player in the quest for sustainable packaging solutions. As the global plastic crisis intensifies, Biodegradable masterbatch enables manufacturers to incorporate eco-friendly materials into their products while maintaining the quality and functionality that consumers expect. According to a report by Smithers Pira, the market for biodegradable plastics is projected to reach USD 15.6 billion by 2025, highlighting the growing demand for sustainable materials in various industries. Biodegradable masterbatch serves as a versatile additive, enhancing plastic substrates by conferring biodegradability and compostability without compromising performance.

When considering biodegradable masterbatch options, it’s essential to be aware of the specific composting conditions required for effective degradation. In many cases, industrial composting facilities are needed to provide the right temperature and humidity to achieve optimal results. Tips for incorporating biodegradable masterbatch include conducting thorough testing to ensure compatibility with existing production processes and clearly labeled packaging to inform consumers about the disposal methods.

Another crucial tip is to stay updated on emerging regulations surrounding biodegradable materials in your region, as these may affect product development and marketing strategies. Research by the European Bioplastics Association indicates that 60% of consumers are increasingly conscious of sustainable packaging, which underscores the need for brands to align their offerings with environmental standards and consumer preferences.

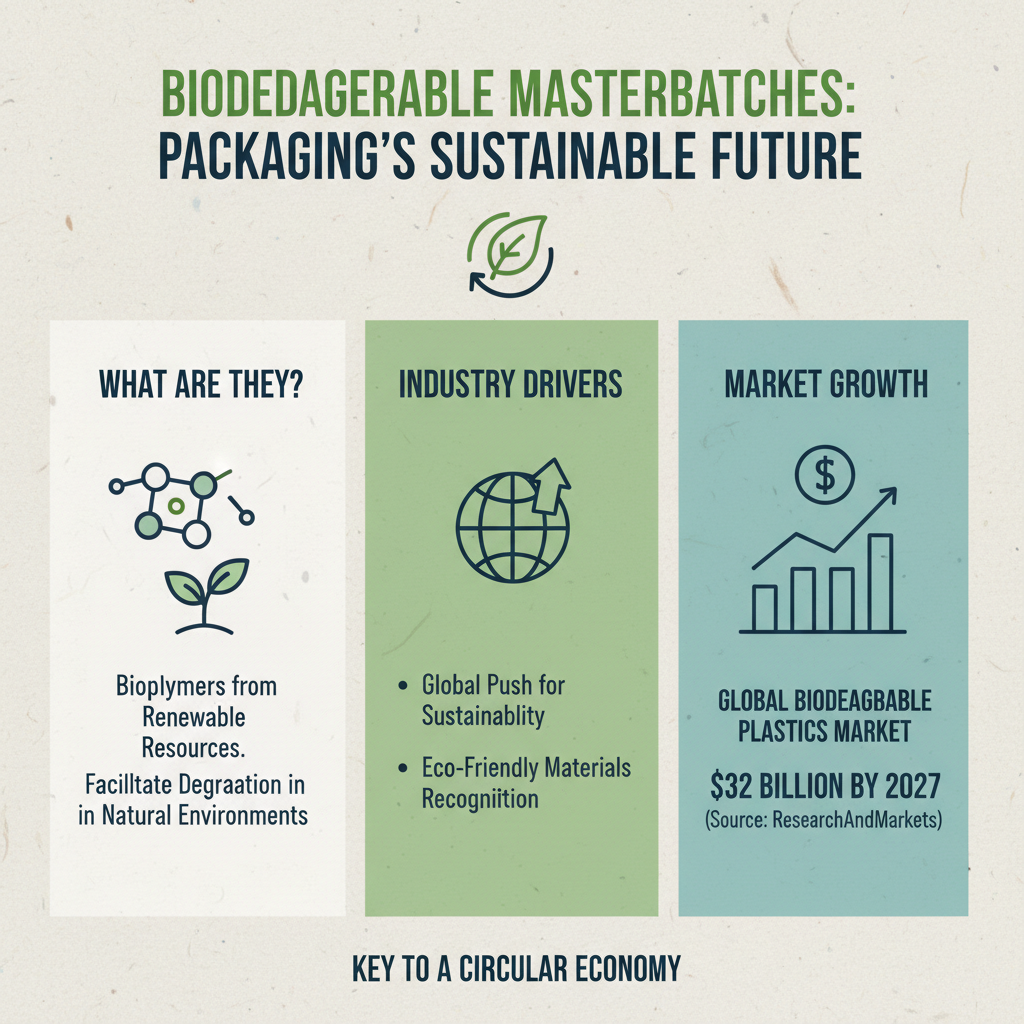

Key Properties of Biodegradable Masterbatches for Eco-Friendly Applications

Biodegradable masterbatches are increasingly becoming essential for the packaging industry, driven by the global push towards sustainable practices. These masterbatches typically contain biopolymers, which are derived from renewable resources, and possess unique properties that facilitate their degradation in natural environments. According to a recent report from ResearchAndMarkets, the global biodegradable plastics market is projected to reach $32 billion by 2027, highlighting the growing recognition of these eco-friendly materials.

Key properties of biodegradable masterbatches include their compatibility with traditional plastics and their ability to retain mechanical strength while enhancing biodegradability. Enhanced formulations often feature additives like starch or polylactic acid (PLA), allowing manufacturers to produce packaging that meets both performance and environmental standards.

For instance, a study published in the Journal of Polymers found that incorporating just 10% of biodegradable additives can significantly reduce the degradation time of conventional polyethylene by up to 60% in industrial composting conditions. This signifies a crucial step towards reducing plastic pollution and meeting the increasing consumer demand for eco-conscious products.

Top Biodegradable Masterbatch Options Available in the Market

As sustainability becomes increasingly important in packaging solutions, biodegradable masterbatches are emerging as a vital option for eco-conscious manufacturers. These formulations enhance the properties of standard plastics and enable them to decompose naturally, reducing the environmental impact. The market offers a variety of biodegradable masterbatch options, each with unique features catering to different applications.

When considering biodegradable masterbatch options, it's essential to understand their compositions. Many of these products incorporate natural polymers, such as PLA (polylactic acid) and PBAT (polybutylene adipate terephthalate), which facilitate biodegradation. Additionally, some masterbatches enhance the mechanical strength and clarity of plastics, making them suitable for diverse uses, from packaging films to containers.

- Evaluate the specific application of the packaging to match the masterbatch's performance characteristics.

- Research suppliers for certifications and test results to ensure compliance with environmental standards.

- Consider blending options with existing materials for improved processing and performance, ensuring that sustainability does not sacrifice quality.

Being informed about the top biodegradable masterbatch options available in the market can help manufacturers and businesses make responsible packaging decisions that align with their sustainability goals.

Comparative Analysis of Performance and Cost in Biodegradable Masterbatches

The burgeoning demand for sustainable packaging has led to a comparative analysis of various biodegradable masterbatch options available in the market. These masterbatches, which enhance the properties of biodegradable polymers, are pivotal in developing eco-friendly packaging solutions. In this analysis, performance indicators such as biodegradability rate, mechanical strength, and processing temperature are evaluated alongside their cost implications. The findings suggest that while some masterbatches excel in biodegradability, they may come with a higher price tag, which can challenge their adoption by manufacturers focused on cost efficiency.

On the other hand, affordable options often compromise on performance, leading to slower degradation rates or inadequate strength for practical applications. It becomes essential for businesses to strike a balance between cost and performance when selecting biodegradable masterbatches. By analyzing different formulations, stakeholders can better understand the trade-offs involved, allowing for informed decisions that align with sustainability goals without sacrificing product integrity or budget constraints. This nuanced understanding is crucial as the industry moves towards more responsible and sustainable packaging practices.

Top 10 Biodegradable Masterbatch Options for Sustainable Packaging Solutions

Future Trends in Biodegradable Masterbatch Technology and Innovations

The future of biodegradable masterbatch technology is rapidly evolving, aligning with the increasing demand for sustainable packaging solutions. Innovations in this sector are aimed at enhancing the performance and environmental benefits of biodegradable materials. Researchers are focusing on developing formulations that not only decompose more efficiently but also retain the mechanical strength and versatility required for various applications. This includes the use of natural additives and bio-based polymers, which help to improve degradation rates under industrial composting conditions.

Moreover, advancements in processing techniques are enabling manufacturers to integrate biodegradable masterbatches more seamlessly into existing production lines. Techniques such as melt blending and twin-screw extrusion are becoming more refined, allowing for better dispersion of biodegradable components within traditional plastic matrices. Future trends also indicate a growing emphasis on transparency and traceability in the supply chain, with companies seeking certifications that highlight their sustainability credentials.

As consumer awareness of environmental issues continues to rise, the adoption of innovative biodegradable masterbatch solutions is set to increase, positioning them at the forefront of sustainable packaging development.

Related Posts

-

Revolutionizing Repair: Understanding the Science Behind Plastic Fillers and Their Environmental Impact

-

10 Essential Tips for Choosing the Right Polyethylene Masterbatch for Your Projects

-

Top 5 Benefits of Using Oxo Biodegradable Products for a Greener Future

-

What is Color Masterbatch and How It Transforms Plastic Manufacturing

-

Top 5 Surya Masterbatch Products to Boost Your Plastic Manufacturing Efficiency

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency