In the construction and heavy equipment industries, the importance of stability and safety cannot be overstated, particularly when it comes to the use of outrigger pads. According to a report by Research and Markets, the global market for construction equipment is projected to reach $250 billion by 2025, highlighting the increasing demand for robust accessories that enhance operational safety. Outrigger pads play a crucial role in distributing the load of machinery, preventing ground failure, and ensuring optimal stability during operations. With China leading the charge in manufacturing high-quality outrigger pads, industry professionals are increasingly turning to these products for unmatched reliability and performance. This blog will delve into the top contenders in the market, showcasing the best outrigger pads available from China's leading manufacturers, and providing a comprehensive comparison to guide your purchasing decisions.

Outrigger pads play a crucial role in construction safety by distributing the weight of equipment and stabilizing machinery, thereby preventing ground failures and accidents. According to a report by the Occupational Safety and Health Administration (OSHA), improper setup of heavy equipment is a leading cause of job site fatalities, accounting for nearly 15% of all construction-related deaths. Using high-quality outrigger pads can significantly enhance stability, mitigating risks associated with heavy lifting and uneven surfaces.

In recent studies, it has been found that using outrigger pads made from advanced composite materials can increase the ground bearing capacity by up to 50%, effectively minimizing the risk of ground penetration in soft soils. As construction projects grow more complex, the demand for reliable outrigger pads has surged. Companies are increasingly relying on leading manufacturers from China that prioritize quality and safety compliance, ensuring that their products meet rigorous industry standards. This emphasis on safety is not just a regulatory requirement; it is a vital component of safeguarding workers and enhancing overall site efficiency.

| Pad Material | Dimensions (mm) | Load Capacity (tons) | Weight (kg) | Applications |

|---|---|---|---|---|

| Polyethylene | 600 x 600 x 50 | 20 | 5 | Cranes, Aerial Lifts |

| Rubber | 500 x 500 x 30 | 15 | 3.5 | Excavators, Forklifts |

| Composite | 800 x 800 x 60 | 25 | 8 | Telehandlers, Rough Terrain Cranes |

| Wood | 700 x 700 x 40 | 10 | 4 | Scaffolding, Heavy Equipment |

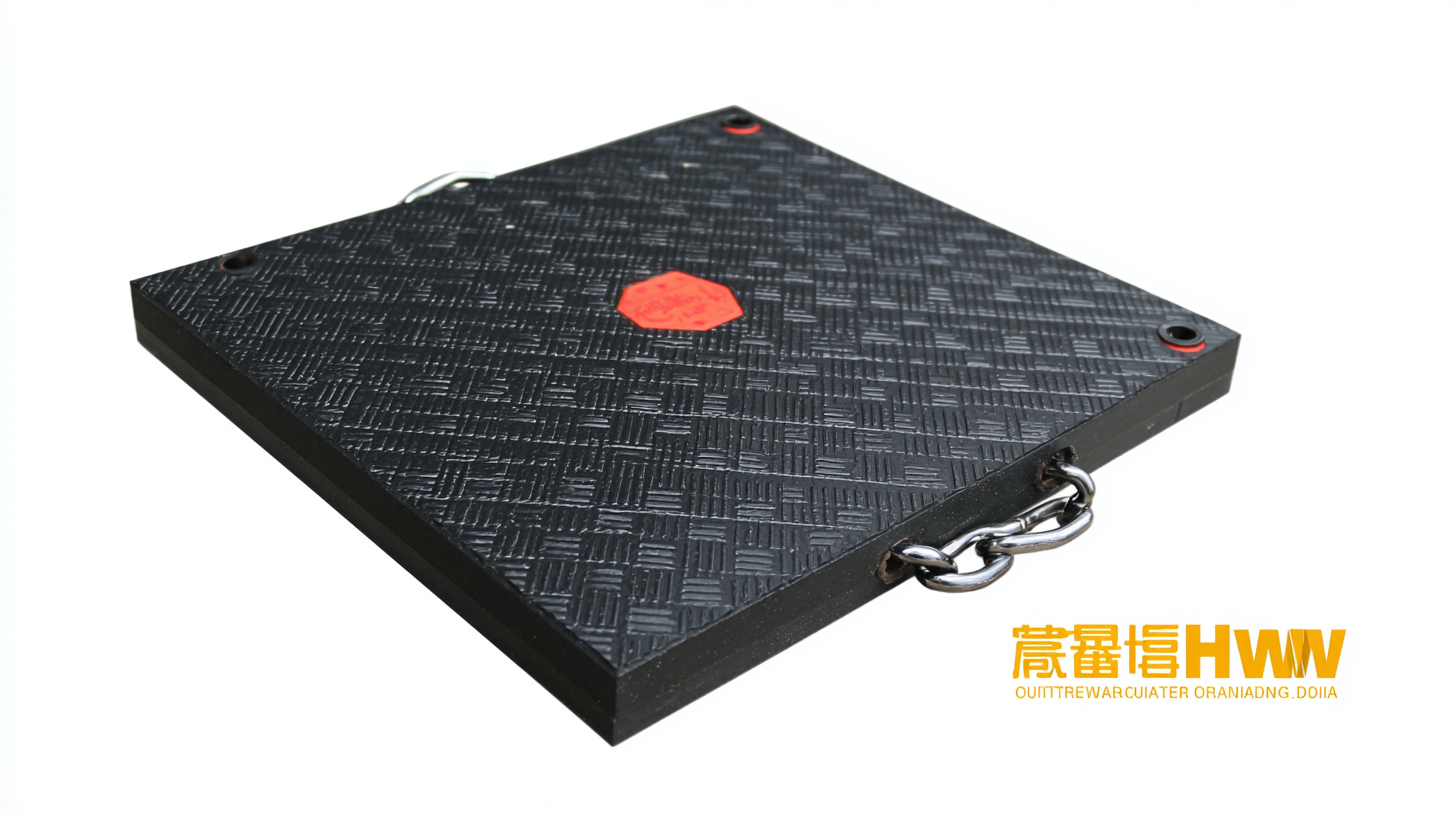

When selecting outrigger pads, quality is paramount. High-quality outrigger pads provide stability and support for heavy machinery, preventing damage to surfaces and ensuring safety on job sites. According to the American National Standards Institute (ANSI), properly engineered outrigger pads can distribute the load up to five times better than standard materials, significantly reducing the risk of ground failure. Therefore, when choosing outrigger pads, look for materials with high-density polyethylene or composite materials that offer durability and resistance to wear.

Another essential feature to consider is the size and thickness of the pads. Industry reports from the Construction Equipment Association (CEA) suggest that the optimal thickness for outrigger pads should be a minimum of 1.5 inches to effectively absorb shock and provide a solid foundation. Additionally, larger surface areas help distribute the weight of the equipment more evenly, which is critical in preventing ground sinking and enhancing the stability of cranes and other heavy equipment.

Manufacturers that implement rigorous testing procedures, meeting ISO 9001 quality management standards, ensure that their outrigger pads meet the necessary specifications for safety and durability, further highlighting the unmatched quality that comes from leading manufacturers in China.

Chinese manufacturers have gained a reputation for producing high-quality outrigger pads, ensuring superior durability through advanced manufacturing techniques and strict quality control standards. The focus on durability is paramount, as outrigger pads must withstand significant weight and stress in various applications, from construction to heavy machinery. By employing innovative materials and processes, these manufacturers guarantee that their products not only meet but exceed industry expectations.

The success of these Chinese manufacturers in achieving unmatched quality hinges on a combination of technological leadership and efficient production methods. Much like in the electric vehicle sector, where firms have slashed development times and improved performance metrics, the outrigger pad industry sees similar advancements. By leveraging economies of scale and investing in research and development, these companies are able to produce durable, reliable pads that are not only cost-effective but also lead the market in performance and longevity. The commitment to quality and innovation reflects a broader trend in China's industrial strategy, focusing on high standards that resonate with global consumer demands.

The performance of outrigger pads is heavily influenced by the materials used in their construction. Innovative materials such as high-density polyethylene (HDPE) and rubber composites are redefining durability and efficiency in this industry. According to a report from the International Journal of Construction Materials, the use of HDPE can increase load distribution by up to 50% compared to traditional wood pads. This is crucial for ensuring stability and safety on various terrains, especially in heavy lifting scenarios.

Tips: When selecting outrigger pads, ensure to choose those made from advanced materials like HDPE or reinforced composites. These materials not only enhance the longevity of the pads but also improve their performance in demanding applications.

Furthermore, the incorporation of innovative materials also leads to lighter and easier-to-handle pads, thus enhancing operational efficiency. A recent market analysis highlights that using lighter compounds can reduce manual handling strain by 30%, allowing operators to focus on precise applications rather than struggling with cumbersome equipment.

Tips: Always prioritize the weight-to-strength ratio of outrigger pads. Investing in the right materials can significantly improve overall project efficiency and worker safety.

When it comes to choosing outrigger pads, many buyers face the dilemma of balancing cost and quality. While cheaper options may seem appealing at first glance, they often lead to greater expenses down the line due to frequent replacements and repairs. Investing in high-quality outrigger pads from China's leading manufacturer ensures durability and performance, ultimately saving money over the long term. These premium pads are designed to withstand substantial weight and environmental stresses, providing a reliable foundation that enhances safety and efficiency at work sites.

Furthermore, selecting quality over quantity can significantly impact overall project costs. By opting for superior outrigger pads, companies can minimize equipment downtime and reduce maintenance expenses, as these products are less prone to wear and tear. The long-lasting nature of these pads means that businesses will not only enjoy peace of mind but also improve operational productivity. In a competitive industry where every dollar counts, prioritizing a one-time investment in durable outrigger pads can lead to significant cost-effectiveness in the long haul.