- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

2026 Best HDPE Compound Options for Your Projects How to Choose?

The demand for HDPE compound continues to rise globally, driven by its versatility and strength. According to a recent industry report, the HDPE market is expected to reach $62 billion by 2026. Many industries, including packaging, construction, and automotive, favor HDPE for its durability and resistance to chemicals. Yet, choosing the right HDPE compound for specific projects can be daunting.

Various HDPE compound options are available, each with unique properties. Factors like density, melt flow index, and additives influence performance. Not all compounds suit every application, which can lead to project setbacks. For instance, a compound with high UV resistance is crucial for outdoor applications. Neglecting these details can result in failure.

While HDPE compounds offer numerous benefits, it’s essential to approach selection thoughtfully. A mismatch in compound specifications may lead to increased costs or reduced functionality. In an industry where every detail counts, making an informed choice is key. Understanding these intricacies will help ensure the success of any project involving HDPE compounds.

Overview of HDPE Compounds and Their Applications

High-Density Polyethylene (HDPE) compounds are increasingly popular in various industries. These materials exhibit excellent chemical resistance and durability. In construction, HDPE is used for piping systems and geomembranes. Reports show that the construction sector accounted for about 30% of HDPE usage in 2022. This trend appears to continue as more projects seek sustainable materials.

The automotive industry also utilizes HDPE for its lightweight properties. Lightweight parts can improve fuel efficiency. According to industry data, HDPE components can reduce vehicle weight by up to 10%. This reduction is essential for meeting stricter emission standards. However, selecting the right HDPE compound can be challenging. Not all compounds share the same qualities. Differences in molecular weight and density can drastically change performance characteristics.

In packaging, HDPE is a top choice due to its recyclability. Many consumers prefer products that are environmentally friendly. HDPE packaging accounts for approximately 40% of the global market. However, not all HDPE is easily recyclable. Understanding the specific application is crucial in ensuring sustainability. Companies must review their material choices seriously.

2026 Best HDPE Compound Options for Your Projects How to Choose? - Overview of HDPE Compounds and Their Applications

| Compound Type | Applications | Key Properties | Color Options | Typical Use Case |

|---|---|---|---|---|

| Standard HDPE | Packaging, Bottles | Excellent chemical resistance, High tensile strength | Natural, Black | Beverage containers |

| HDPE with UV Stabilizer | Outdoor applications, Pipes | Enhanced UV resistance, Impact strength | Natural, Black, Blue | Agricultural tubing |

| Reinforced HDPE | Heavy-duty applications, Industrial containers | Increased strength, Stiffness | Gray, Black | Storage tanks |

| HDPE for 3D Printing | Prototyping, Custom parts | Good flowability, Low shrinkage | Varied colors | Prototype creation |

| Color Masterbatch HDPE | Consumer goods, Toys | Vibrant colors, Consistent coloring | Multiple colors | Colorful products |

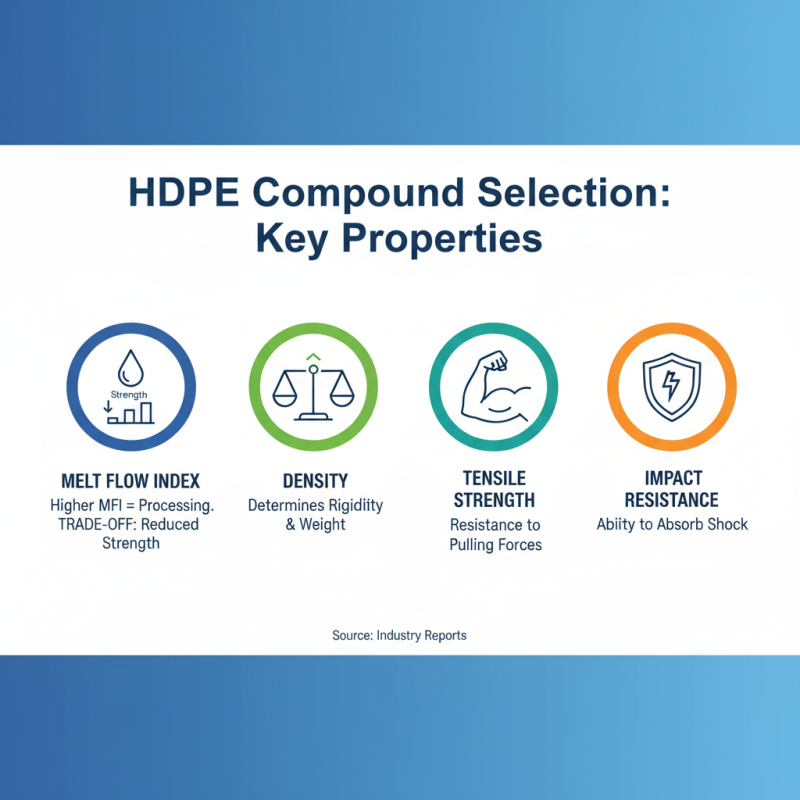

Key Properties to Consider When Selecting HDPE Compounds

When selecting HDPE compounds for your projects, several key properties deserve careful consideration. These include melt flow index, density, tensile strength, and impact resistance. According to recent industry reports, a higher melt flow index often correlates with easier processing. However, this can reduce mechanical strength, which is a trade-off that needs reflection.

Density plays a crucial role in determining the stiffness and durability of the final product. HDPE compounds typically range from 0.94 to 0.97 g/cm³. It’s essential to understand that while lower density options may be lightweight and cost-effective, they may compromise structural integrity. Tensile strengths can vary significantly; many applications require compounds that exceed 20 MPa. Using materials below this threshold could lead to failure under stress.

Another critical aspect is the impact resistance of HDPE compounds. Products designed for outdoor use must withstand UV exposure and varying temperatures, which can lead to brittleness over time. Some reports suggest that additives can improve this resistance. However, it’s vital to test these compounds under real-world conditions to ensure they meet specific project needs.

Comparative Analysis of Popular HDPE Compound Options for 2026

When selecting HDPE compounds for your projects in 2026, there are several popular options to consider. These compounds vary in properties such as strength, flexibility, and Environmental Stress Crack Resistance (ESCR). Understanding these factors is crucial for making a well-informed choice. Certain compounds may offer higher durability, while others excel in toughness. This makes the decision more complex than it initially seems.

Many projects require specific characteristics from the materials used. For instance, applications that involve exposure to chemicals often need HDPE compounds with superior ESCR. On the other hand, projects focused on flexibility might prioritize softer compounds. One might assume that a higher price equates to better quality, but that's not always the case. Sometimes, a budget-friendly option might perform just as well as its pricier counterparts.

It’s important to assess your project’s unique demands critically. Testing a few options before making a bulk purchase can help. Explore various formulations to see which one meets your expectations. While popular compounds might be well-recommended, they aren't a one-size-fits-all solution. Your project may have requirements that challenge conventional choices.

Guidelines for Choosing the Right HDPE Compound for Your Project

When choosing the right HDPE compound for your project, several factors come into play. Understanding your project's requirements is crucial. Consider the application, environmental conditions, and mechanical properties needed. HDPE compounds vary widely in flexibility and strength. Assess the specific demands your project makes on these materials.

Tips: Look for compounds with good UV resistance if exposed to sunlight. Ensure the compound can handle the temperature range it may face. This helps prevent future failures.

It’s essential to think about the processing methods too. Different HDPE compounds have varying compatibilities with fabrication techniques, like injection molding or extrusion. Your equipment may not work well with all compounds. Examine how each compound behaves during processing and how it influences your end product's quality.

Tip: Always request samples before making large orders. This helps you test how well the compound meets your needs. You might discover that a seemingly ideal option doesn’t perform as expected. Consider feedback from others in your industry. Learning from their experiences can save you time and money.

2026 Best HDPE Compound Options for Your Projects

Future Trends in HDPE Compounds and Their Impact on Selection

The landscape of HDPE compounds is rapidly evolving, influenced by a combination of technological advancements and environmental considerations. According to recent data from industry analyses, the global demand for sustainable materials is projected to grow by 15% annually through 2026. This trend drives manufacturers to innovate and improve the environmental profile of HDPE compounds.

Enhanced additives like bio-based plasticizers are becoming more mainstream. These innovations aim to reduce reliance on fossil fuels and improve biodegradability. A study highlighted that 70% of companies are now prioritizing eco-friendly materials in their project specifications. However, there’s a struggle. Not all innovations come with reliable performance data. Some compounds fail to deliver desired properties under varying conditions, creating uncertainty in selection.

The future also points toward advancements in recycling technology. Closed-loop systems for HDPE recycling are expected to increase by nearly 25% within the next few years. However, this growth invites debate. Will the quality of recycled HDPE compound match that of virgin materials? It's an important question for designers and engineers as they choose their materials. Addressing these uncertainties will be crucial for successful projects.

Related Posts

-

Top 5 Cable Compounds: Key Types and Their Applications Explained

-

How to Choose the Right Plastic Color Masterbatch for Your Projects

-

2025 Guide: How to Choose the Right Compound Filler for Your Projects

-

Exploring the Fascinating World of Plastic Effects: How They Transform Our Everyday Materials

-

2025 Top Cable Compounds: Trends, Innovations, and Industry Insights

-

What is Color Masterbatch and How It Transforms Plastic Manufacturing