- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

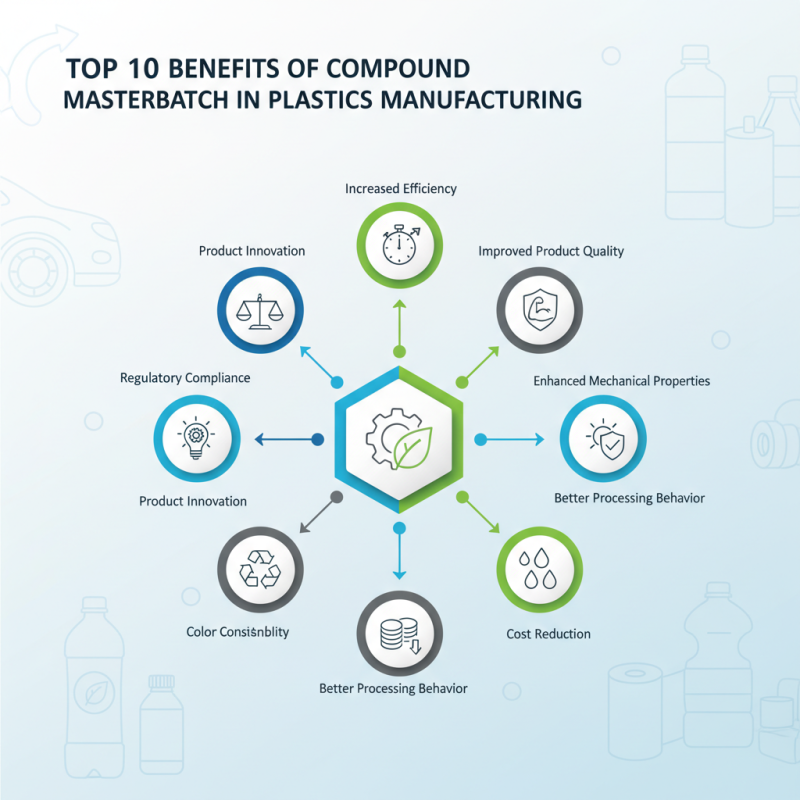

Top 10 Benefits of Using Compound Masterbatch in Plastics Manufacturing

The plastics manufacturing industry is facing increasing demands for efficiency, sustainability, and product innovation. One of the pivotal advancements that have emerged in response to these needs is the use of compound masterbatch. According to the Plastics Industry Association, the U.S. plastics sector alone generates over $400 billion annually, and the incorporation of masterbatch solutions is projected to revolutionize production processes. Compound masterbatch, a concentrated mixture of additives and pigments, provides manufacturers with the ability to enhance the performance of plastics, improve production efficiency, and achieve consistent quality in their final products.

Recent studies indicate that the global masterbatch market is expected to reach $13.3 billion by 2026, with a significant portion attributed to the growing application of compound masterbatch across various sectors such as packaging, automotive, and consumer goods. The benefits of utilizing compound masterbatch extend far beyond mere color enhancement; they include improvements in mechanical properties, UV protection, and processing behavior, ultimately leading to more sustainable and eco-friendly products. As manufacturers strive to meet evolving consumer preferences and regulatory standards, understanding the top benefits of compound masterbatch becomes essential to harnessing its full potential in plastics production.

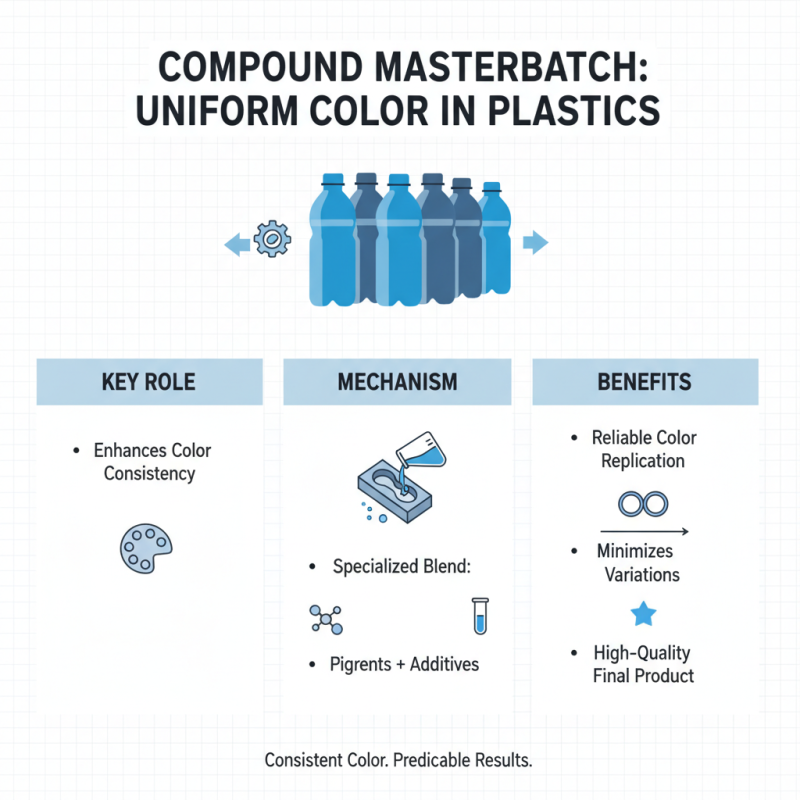

Benefits of Compound Masterbatch in Enhancing Color Consistency in Plastics

Compound masterbatch plays a pivotal role in enhancing color consistency in plastics manufacturing, which is crucial for ensuring a high-quality final product. This specialized blend of pigments and additives allows manufacturers to achieve uniform color replication across large production runs. By using compound masterbatch, variations that can occur due to different processing conditions or materials can be minimized, resulting in a more predictable and reliable color output.

Moreover, the integration of compound masterbatch not only improves color consistency but also aids in achieving deeper and more vibrant hues. The uniform distribution of pigments throughout the plastic matrix ensures that colors maintain their integrity during production and throughout the lifetime of the product. This consistency is particularly important for brands that prioritize aesthetic appeal and consumer satisfaction, as it helps to build trust and loyalty among their customer base. By investing in compound masterbatch, manufacturers can effectively elevate their product quality while reducing waste and ensuring a more efficient manufacturing process.

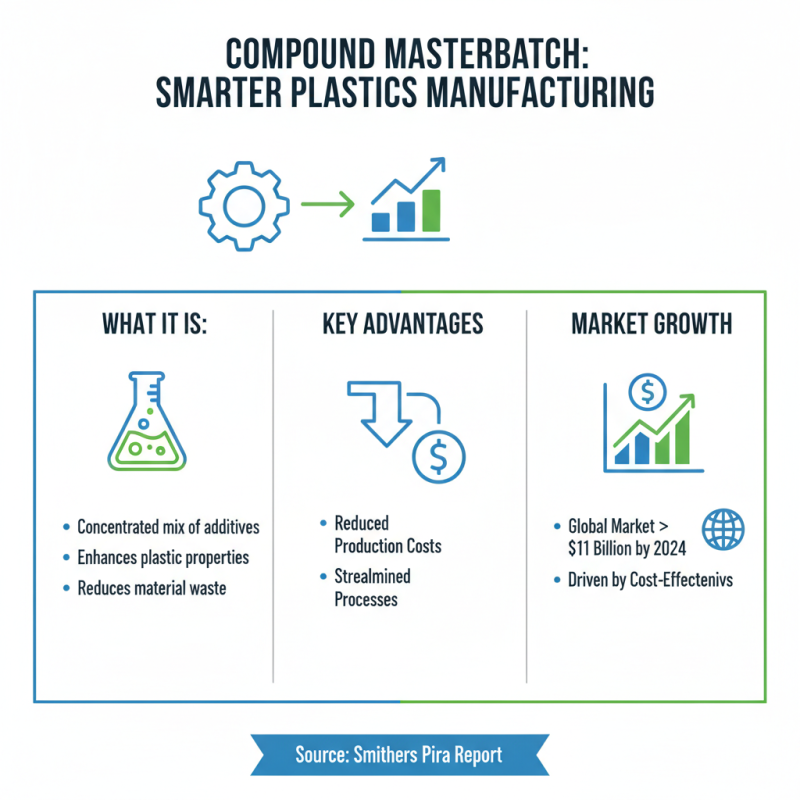

Impact of Compound Masterbatch on Reducing Production Costs in Manufacturing

The use of compound masterbatch in plastics manufacturing presents significant advantages, particularly in reducing production costs. According to a report by Smithers Pira, the global market for masterbatch is expected to exceed $11 billion by 2024, largely driven by demand for cost-effective solutions in polymer processing. Compound masterbatch serves as a concentrated mixture of additives that enhances the properties of plastics, allowing manufacturers to streamline their processes and reduce material waste.

By incorporating compound masterbatch, manufacturers can achieve improved color consistency and performance without the need for extensive machinery adjustments. Studies indicate that utilizing masterbatch can lead to a reduction in raw material costs by up to 30%, as it allows for more precise and efficient use of additives. This efficiency is particularly crucial in high-throughput environments, where minimizing downtime and material waste directly impacts the bottom line. Furthermore, the ability to produce specialized formulations with minimal additional steps not only lowers costs but also accelerates time-to-market for new products, allowing companies to respond swiftly to market demands.

Role of Compound Masterbatch in Improving Plastic Mechanical Properties

The use of compound masterbatch in plastics manufacturing has emerged as a key factor in enhancing the mechanical properties of plastic products. By incorporating various additives into a polymer base, compound masterbatch allows manufacturers to tailor the characteristics of the final product to meet specific requirements. This customization leads to improved tensile strength, impact resistance, and stiffness, which are critical for applications where durability and performance are paramount.

Furthermore, compound masterbatch enhances the processing efficiency of plastics. The even dispersion of additives within the polymer matrix ensures consistent mechanical properties throughout the material. This homogeneity results in fewer defects during production and helps in maintaining dimensional stability and durability in the end products. Additionally, the use of specialized masterbatches can facilitate better flow characteristics during molding operations, enabling manufacturers to achieve precise shapes and reduce production waste. Overall, the role of compound masterbatch in improving mechanical properties is indispensable for meeting the evolving demands of modern plastic applications.

Top 10 Benefits of Using Compound Masterbatch in Plastics Manufacturing

| Benefit | Description | Impact on Mechanical Properties |

|---|---|---|

| Enhanced Coloration | Provides vibrant and uniform color throughout plastics. | Improves aesthetic appeal and marketability. |

| Improved Dispersion | Ensures even distribution of additives in the polymer matrix. | Enhances mechanical strength and reduces defects. |

| Cost Efficiency | Reduces material costs by minimizing waste and enhancing properties. | Allows for lower density materials without sacrificing strength. |

| Tailored Properties | Customizable formulations to suit specific application needs. | Enables targeted enhancements to tensile and flexural properties. |

| Consistency in Quality | Ensures uniform quality across production batches. | Reduces variability in mechanical performance. |

| Reduced Processing Issues | Minimizes melt flow and thermal stability problems. | Improves flow characteristics, enhancing moldability. |

| Increased Durability | Strengthens resistance to physical wear and tear. | Extends service life and reduces failure rates. |

| Eco-Friendliness | Facilitates the incorporation of recycled materials. | Improves environmental sustainability of the product. |

| Enhanced UV Stability | Provides better protection against UV degradation. | Preserves physical properties over prolonged exposure. |

| Improved Thermal Properties | Modifies thermal stability and processing temperatures. | Enhances overall performance in high-temperature applications. |

Environmental Advantages of Using Compound Masterbatch in Plastics Production

The use of compound masterbatch in plastics production offers significant environmental advantages that align with the growing need for sustainable manufacturing practices. One of the primary benefits is the reduction of waste. With compound masterbatch, manufacturers can achieve precise color matching and material properties right in the production process. This precision leads to less scrap and off-spec materials, minimizing the environmental impact associated with excess waste disposal.

Additionally, compound masterbatch facilitates the recycling of plastics. By utilizing a concentrated additive form, it allows for greater control over the enhancement of recycled materials without compromising the quality of the final product. This means that recycled plastics can be reprocessed with less energy and fewer new raw materials, leading to lower carbon emissions. Furthermore, the ability to incorporate sustainable additives within the masterbatch, such as those derived from renewable resources, supports the transition towards a circular economy in the plastics industry, ensuring that valuable resources are reused rather than discarded.

Technological Advances in Compound Masterbatch Applications in the Industry

Recent technological advances in compound masterbatch applications have significantly transformed the plastics manufacturing industry. With the introduction of sophisticated compounding techniques, manufacturers can achieve enhanced color consistency and greater compatibility with various polymer matrices. This has led to the development of masterbatches that can be tailored to meet specific performance requirements, such as UV resistance, anti-static properties, or flame retardancy. As a result, the versatility of compound masterbatch has grown, facilitating its use in a wider range of applications from consumer goods to electrical components.

Additionally, innovative processing technologies are enabling more efficient production methods. For instance, advancements in extrusion and blending technologies ensure a more uniform distribution of additives within the plastic matrix, improving the overall quality of the final products. These advancements not only help in reducing material wastage but also lower energy consumption during production, contributing to more sustainable manufacturing practices. The continuous evolution in the formulation of compound masterbatches opens doors to new functionalities, ensuring that the plastics industry can adapt to changing consumer demands and regulatory standards.

Top 10 Benefits of Using Compound Masterbatch in Plastics Manufacturing

This bar chart illustrates the top benefits of using compound masterbatch in the plastics manufacturing industry. The data highlights the key advantages such as improved processing efficiency, enhanced product quality, and cost-effectiveness.

Related Posts

-

Exploring the Benefits of Compound Masterbatch: Industry Trends and Performance Metrics for 2024

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency

-

The Role of White Masterbatch in Enhancing Sustainable Plastic Solutions

-

2025's Top 10 Plastic Filler Masterbatch Innovations for Enhanced Performance

-

2025 Top Compound Cable Types for Enhanced Connectivity Solutions

-

Exploring the Benefits of Using White Masterbatch in Sustainable Plastic Production