- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

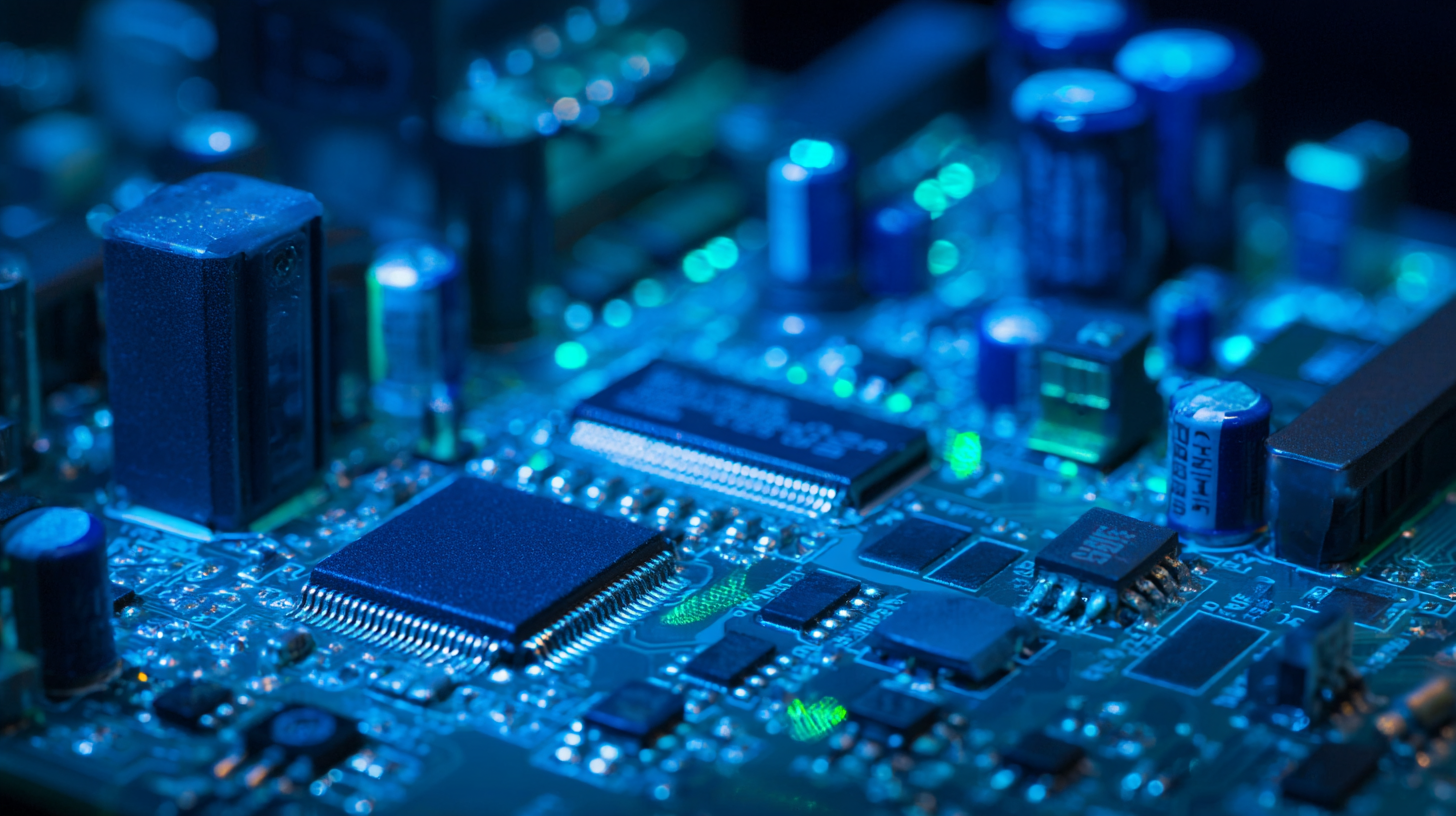

Understanding the Benefits of Anti Static Plastic in Electronics Packaging

In the rapidly evolving world of electronics, the packaging materials used play a crucial role in ensuring product safety and reliability. One such material that has gained significant attention is anti static plastic. This type of plastic is designed to mitigate the risks associated with electrostatic discharge (ESD), which can cause serious damage to sensitive electronic components. Understanding the benefits of anti static plastic in electronics packaging is essential for manufacturers and consumers alike, as it not only protects valuable products during transport and storage but also contributes to enhancing overall performance and longevity. This guide will explore the various advantages of incorporating anti static plastic into packaging solutions, including its effectiveness in preventing ESD, its impact on product integrity, and considerations for selecting the right type of anti static plastic for specific applications. Through this exploration, we aim to highlight the critical role that this material plays in the electronics industry.

Benefits of Anti Static Plastic in Safeguarding Electronics During Transport

Anti-static plastic plays a crucial role in safeguarding electronics during transport, particularly in an industry where static electricity can lead to significant damage. The use of anti-static packaging materials helps prevent electrostatic discharge (ESD), which is a sudden flow of electricity that can compromise the integrity of sensitive electronic components. By utilizing this type of packaging, manufacturers can ensure that their products arrive at their destination without the risk of malfunction or failure, thereby reducing return rates and enhancing customer satisfaction.

Anti-static plastic plays a crucial role in safeguarding electronics during transport, particularly in an industry where static electricity can lead to significant damage. The use of anti-static packaging materials helps prevent electrostatic discharge (ESD), which is a sudden flow of electricity that can compromise the integrity of sensitive electronic components. By utilizing this type of packaging, manufacturers can ensure that their products arrive at their destination without the risk of malfunction or failure, thereby reducing return rates and enhancing customer satisfaction.

Moreover, anti-static plastics are designed to dissipate static charges, creating a safer environment for electronic items throughout the shipping process. They are lightweight and versatile, making them an ideal choice for various packaging needs. This not only helps in maintaining the electronics’ functionality but also supports sustainability efforts by minimizing material waste. As the demand for high-quality electronic products continues to rise, the importance of anti-static plastic in transportation becomes increasingly evident, providing a reliable solution for protecting valuable technology during its journey.

Key Properties of Anti Static Materials for Effective Electronics Packaging

Anti-static materials play a crucial role in electronics packaging, safeguarding sensitive components from electrostatic discharge (ESD). According to a report by the ESD Association, nearly 30% of all product failures in the electronics industry are attributed to ESD, underscoring the necessity for effective anti-static solutions. Anti-static plastic helps reduce the generation of static electricity through its inherent properties, making it ideal for packaging high-value electronic items.

The key properties of anti-static materials include their ability to dissipate static charges and prevent the accumulation of static electricity on their surfaces. This is typically achieved through the incorporation of static-dissipative additives during the manufacturing process. For instance, according to a study by Freedonia Group, the demand for anti-static packaging materials is projected to grow by 5.5% annually, reaching over $1 billion by 2025. This growth is driven by an increasing awareness of ESD risks and the need for robust protections that anti-static plastics provide, ensuring the longevity and reliability of electronic products during storage and transportation.

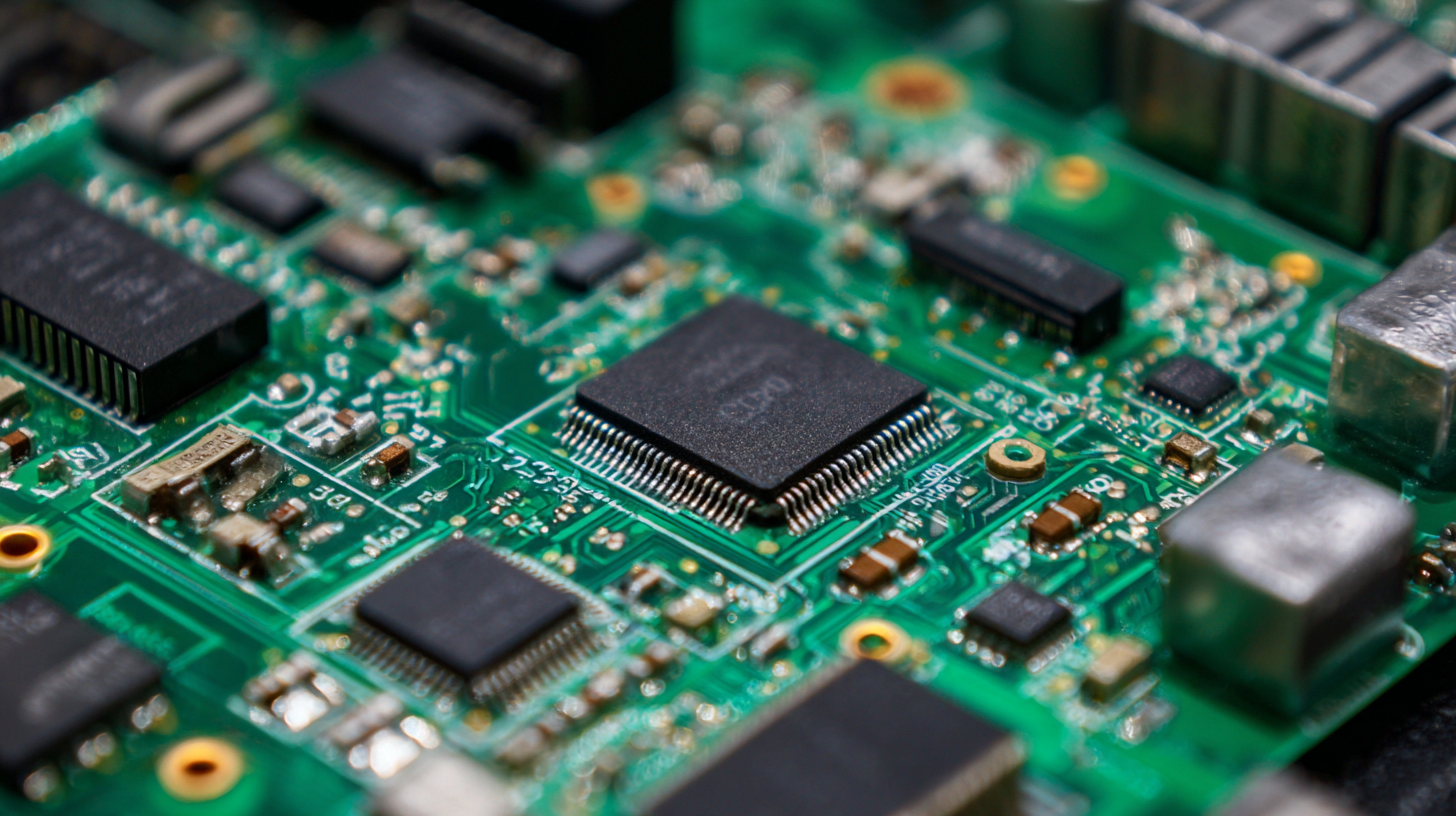

Comparison of Traditional vs. Anti Static Packaging Solutions in Electronics

When comparing traditional packaging solutions with anti-static packaging in the electronics sector, the advantages of anti-static plastic become evident. Traditional packaging materials often fail to offer sufficient protection against electrostatic discharge (ESD), which can lead to significant damage to sensitive electronic components. According to a report by the ESD Association, nearly 30% of product failures in electronics can be attributed to ESD damage. In contrast, anti-static plastics are specifically designed to dissipate static electricity and reduce the risks associated with static build-up, ensuring a safer environment for sensitive devices during transit and storage.

Moreover, anti-static packaging solutions provide not only ESD protection but also offer greater versatility in handling and customization. A study by Smithers Pira indicates that the market for anti-static packaging is expected to grow at a CAGR of 5.6% from 2021 to 2026, indicating a shift in industry preference towards these innovative solutions. The use of anti-static materials minimizes the need for additional layers of protection, thereby optimizing packaging processes and reducing overall costs in the long run. This evolution illustrates how manufacturers are recognizing the critical importance of using specialized materials to safeguard their products while enhancing their operational efficiency.

Impact of Anti Static Plastic on Product Longevity and Performance

Anti-static plastics play a crucial role in enhancing the longevity and performance of electronic products by minimizing damage from electrostatic discharge (ESD). In electronics packaging, these materials are specifically designed to dissipate static electricity, preventing the buildup that can lead to component failure. By utilizing anti-static plastics, manufacturers can protect sensitive electronic components during shipping and handling, ultimately extending the lifespan and reliability of the products.

Furthermore, the impact of anti-static plastics extends beyond just protection; they also contribute to improved performance in operational environments. When electronic components are housed in anti-static packaging, the risk of short circuits and performance degradation is significantly reduced. This is particularly important in the growing market for electric vehicles (EVs), where the reliability of electronic systems is paramount. As the demand for conductive and anti-static solutions continues to rise, investments in advanced formulations of these plastics are essential for ensuring the quality and durability of electronic products across various applications.

Understanding the Benefits of Anti Static Plastic in Electronics Packaging - Impact of Anti Static Plastic on Product Longevity and Performance

| Feature | Description | Impact on Longevity | Impact on Performance |

|---|---|---|---|

| Static Dissipation | Reduces the buildup of static electricity during handling and shipping. | Increases shelf life by preventing static damage to sensitive components. | Maintains operational integrity of electronic devices. |

| Durability | Resistant to moisture, chemicals, and physical impacts. | Enhances lifespan of the packaging and the product. | Ensures consistent performance under various conditions. |

| Lightweight Design | Easy to handle and reduces shipping costs. | Lowers transportation impacts on the product. | Facilitates better energy efficiency in logistics. |

| Customization | Can be tailored to fit specific product dimensions and configurations. | Improves fit and protection for various electronic products. | Enhances user experience and satisfaction. |

| Cost-Effectiveness | Reduces potential damages, leading to lower replacement costs. | Maximizes return on investment over time. | Supports reliable product performance across its lifespan. |

Environmental Considerations and Sustainability of Anti Static Plastic Usage

The growing concern for environmental sustainability has led to the increased use of anti-static plastics in electronics packaging. These materials not only protect sensitive electronic components from static damage but also offer benefits that align with eco-friendly practices. Many anti-static plastics are recyclable, reducing landfill waste and promoting circular economy practices. By opting for these materials, manufacturers can minimize their environmental footprint while ensuring product safety.

Tips for using anti-static plastic in packaging include selecting materials with high recyclability and low toxicity. It's essential to look for certifications that guarantee eco-friendliness, ensuring that the packaging does not contribute to harmful environmental impacts. Additionally, consider bulk purchasing to decrease packaging waste and optimize resource use, making a significant difference in overall sustainability.

Furthermore, adopting a life-cycle perspective when evaluating anti-static materials can enhance their environmental benefits. This involves assessing the entire production, usage, and disposal process, thereby identifying opportunities for improvement. By integrating these considerations, companies can not only meet regulatory requirements but also appeal to increasingly eco-conscious consumers.

Related Posts

-

Unlocking the Benefits of Anti Block Masterbatch: Revolutionizing Plastics with Enhanced Performance

-

Unlocking Creativity: How Special Effect Masterbatches Transform Modern Plastics with 30% Enhanced Visual Appeal

-

Unlocking Creative Potential: How Color Master Batches Transform Plastic Manufacturing

-

Exploring the Future of EVA Masterbatch: Trends and Innovations in Polymer Additives for 2024

-

Unlocking the Potential of Filler Masterbatch: Innovations in Polymer Manufacturing

-

Exploring the Benefits of Compound Masterbatch: Industry Trends and Performance Metrics for 2024