- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

Why is Anti Block Masterbatch Essential for Packaging Industry Success?

The packaging industry faces significant challenges in material performance and efficiency. According to a report by Smithers Pira, the global market for packaging is projected to reach $1 trillion by 2024. To meet increasing demands, manufacturers are turning to advanced solutions like anti block masterbatch. This additive plays a vital role in enhancing the performance of films, especially in preventing unwanted adhesion between layers.

Recent statistics reveal that nearly 30% of packaging materials are still prone to blockages during processing and storage. This issue can lead to production delays and increased costs, affecting overall profitability. By incorporating anti block masterbatch, companies can significantly reduce these risks. Proper utilization of this additive can lead to smoother operations and minimize waste.

However, not all anti block masterbatch products are created equal. Some may underperform or fail to meet specific requirements, leading to frustration for manufacturers. It is crucial for the industry to focus on quality and tailor solutions to suit varying needs. The effectiveness of anti block masterbatch is essential in achieving a successful packaging strategy, driving innovation, and improving sustainability in the long run.

The Role of Anti Block Masterbatch in Packaging Materials

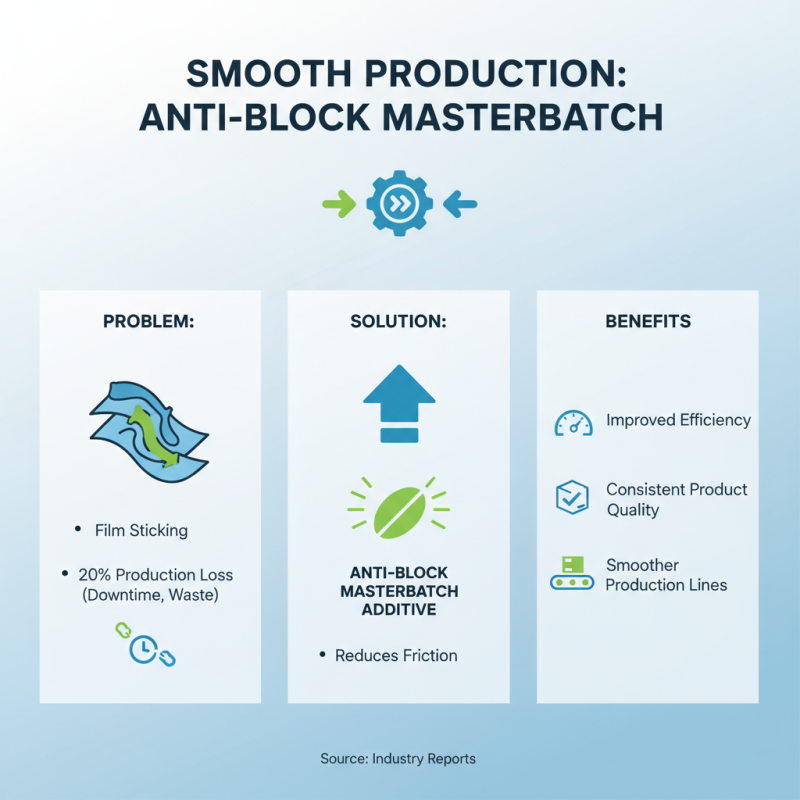

The use of anti-block masterbatch in packaging materials is vital for efficiency and product quality. This additive reduces friction between layers of films. It prevents sticking, making processes smoother in production lines. According to industry reports, improper sticking can lead to significant downtime. A survey indicates that companies lose about 20% of production time due to film handling issues.

Choosing the right anti-block masterbatch improves clarity and reduces haze in packaging films. This is particularly important for consumer products. Studies show that over 70% of customers prefer packaging that showcases the product. Enhancing visibility can drive sales. However, not all masterbatches perform equally. Some may alter the mechanical properties negatively, causing fragility.

**Tip:** Always conduct thorough testing before finalizing your masterbatch selection. Evaluate both functionality and cost-efficiency. Investing in quality can prevent larger losses down the line. Monitor your production processes closely. If sticking occurs, revisit your material choices to optimize performance.

Understanding the Functionality of Anti Block Masterbatch

Anti Block Masterbatch plays a crucial role in the packaging industry. It prevents plastic films from sticking together. This functionality is vital during production and storage.

When films cling, manufacturers face delays and increased costs. Such issues can disrupt supply chains. Using this masterbatch effectively reduces these risks.

The composition of Anti Block Masterbatch is simple yet effective. It often contains mineral fillers. These fillers create a physical barrier between films. The right amount and distribution are essential.

Too little might not work, while too much can alter the film's properties. Balancing these components can be challenging. Manufacturers must often experiment to find the right mix.

The impact of Anti Block Masterbatch extends beyond production. It ensures the easy handling of packaged goods. Efficient packaging increases customer satisfaction and reduces waste. However, there are concerns about the environmental impact.

Many are looking for sustainable alternatives. This aspect is worth reflecting on as the industry progresses.

Benefits of Using Anti Block Masterbatch in Packaging Applications

The packaging industry faces many challenges. One key issue is the sticking of films and sheets during processing and handling. Anti block masterbatch can effectively address this concern. According to industry reports, using anti block additives can reduce film blocking by up to 90%. This allows for smoother handling and greater efficiency in production.

Moreover, anti block masterbatch improves the aesthetic quality of packaged products. It prevents surfaces from sticking together, preserving the visibility and integrity of the packaging. Many manufacturers have reported a 30% increase in production speed when employing these additives. This leads to cost savings and meets consumer demands for quality.

However, not all anti block masterbatches are created equal. Some formulations may not perform well under all conditions. Testing and understanding specific needs is vital. There is ongoing research in enhancing the effectiveness and sustainability of these masterbatches, which remains crucial for future advancements in packaging solutions. Balancing cost and performance is a continuous challenge for the industry.

Why is Anti Block Masterbatch Essential for Packaging Industry Success? - Benefits of Using Anti Block Masterbatch in Packaging Applications

| Benefit | Description | Impact on Packaging |

|---|---|---|

| Improved Flowability | Enhances the flow of plastic materials during processing. | Results in uniform thickness and better molding. |

| Reduced Blocking | Minimizes adhesion between films during storage and transport. | Improves product accessibility and appearance. |

| Enhanced Clarity | Maintains optical properties of the packaging material. | Attracts consumers with better visibility of the product. |

| Cost Efficiency | Allows reduction in the amount of polymer needed for production. | Leads to overall lower production costs. |

| Compatibility | Can be easily integrated with various polymers. | Provides flexibility in choosing materials for different applications. |

Impact of Anti Block Masterbatch on Production Efficiency

The use of Anti Block Masterbatch in the packaging industry dramatically influences production efficiency. Studies indicate that incorporating anti-block agents can reduce film sticking by over 60%. This reduction minimizes downtime during the production process. Operators benefit from fewer disruptions, which boosts overall productivity.

In addition to minimizing blockages, Anti Block Masterbatch enhances film clarity. A report by a leading industry analyst noted that clearer films can improve customer appeal by nearly 30%. This advancement not only satisfies consumer demands but also adds value to products on the shelf. However, it’s essential to consider the balance between clarity and functionality. Excessive use of anti-block agents could lead to compromised mechanical properties.

Moreover, there is ongoing debate about optimal usage levels. Some manufacturers report inconsistent results when experimenting with various formulations. This inconsistency may stem from variations in raw materials and processing conditions. Striking the right balance is crucial, as too much anti-block can lead to increased costs without added benefits.

Future Trends in Anti Block Masterbatch for the Packaging Industry

The packaging industry is evolving rapidly.

Anti block masterbatches play a crucial role in enhancing packaging materials.

They prevent sheets from sticking together, ensuring smooth production processes.

However, the industry faces challenges in adopting these materials. Many companies still operate with

outdated practices. This can lead to increased waste and inefficiencies.

Future trends indicate that anti block masterbatches will become more sophisticated. Innovations may include biodegradable options that cater to sustainability. Companies might explore new formulations to improve clarity and durability.

Still, there’s a need for reflection. Not all manufacturers invest in R&D for these advancements. This creates a gap in quality that can affect the end product.

As consumer preferences shift towards eco-friendly packaging, the demand for advanced anti block solutions will rise.

However, embracing these trends requires an open mindset. The future belongs to those willing to

adapt and innovate. Incremental steps towards improvement are essential.

Companies must not overlook the importance of quality in this competitive landscape.

Related Posts

-

Unlocking the Potential of Filler Masterbatch: Innovations in Polymer Manufacturing

-

Why Choose the Right Cable Compound for Your Electrical Projects?

-

2025's Top 10 Plastic Filler Masterbatch Innovations for Enhanced Performance

-

10 Best Special Effect Masterbatches for Stunning Visuals in Plastics?

-

2025 Top Compound Cable Types for Enhanced Connectivity Solutions

-

How to Choose the Right Plastik Masterbatch for Your Needs?