- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

2025 Top Trends in Color Masterbatch for Sustainable Plastic Solutions

In recent years, the plastic industry has been under increasing pressure to adopt sustainable practices, leading to a significant evolution in the design and application of color masterbatch. According to a report by MarketsandMarkets, the global masterbatch market is projected to reach USD 14.37 billion by 2025, with a notable shift towards eco-friendly alternatives taking center stage. As consumers and manufacturers alike become more environmentally conscious, the demand for sustainable color masterbatch solutions is expected to rise sharply.

Expert insights from Dr. James Thompson, a leading authority in the plastics industry, emphasize the growing importance of sustainability in color masterbatch production: "The future of color masterbatch lies not only in its ability to enhance aesthetics but also in its potential to contribute to a circular economy." This sentiment underscores a crucial trend, where innovative techniques and biodegradable materials are being developed to reduce plastic waste while maintaining vibrant color solutions.

As we look towards 2025, it is clear that the integration of sustainable practices in color masterbatch formulation will not only redefine product offerings but also set the standard for industry success. With advancements in technology and materials, the path to more sustainable plastic solutions is becoming clearer, paving the way for a greener future in the plastics landscape.

Emerging Sustainability Trends in Color Masterbatch Technologies

The color masterbatch industry is witnessing significant shifts towards sustainability, driven by increasing consumer awareness and regulatory pressures. According to a recent market analysis by Smithers, the global demand for sustainable masterbatches is projected to grow at a CAGR of 6.5% from 2023 to 2028. This shift is propelling innovations in the development of eco-friendly color masterbatches made from renewable resources. Emerging technologies, such as bio-based additives and recyclable pigments, are reshaping how manufacturers approach color solutions, enhancing the overall sustainability profile of plastic products.

One of the noteworthy trends is the incorporation of post-consumer recycled (PCR) materials in color masterbatch production. The latest industry reports indicate that approximately 45% of consumers are now inclined to purchase products made from recycled materials. This consumer preference is influencing manufacturers to invest in R&D focused on integrating PCR into their offerings, ensuring that color does not compromise performance or aesthetic appeal. Moreover, advancements in processing technologies allow for better dispersion and compatibility of these recycled materials, leading to improved product quality.

Tips for manufacturers include prioritizing collaboration with suppliers who specialize in sustainable materials and seeking certifications that highlight eco-friendly practices. Investing in technology that enhances quality while reducing environmental impact should also be a priority. As the industry continues to evolve, embracing these sustainability trends will be crucial for businesses looking to thrive in an increasingly eco-conscious market.

Innovations in Biodegradable Color Masterbatches for Eco-Friendly Plastics

As the demand for sustainable plastic solutions grows, innovations in biodegradable color masterbatches are poised to revolutionize the industry. According to a recent report by Research and Markets, the global biodegradable plastics market is projected to reach USD 19.93 billion by 2025, driven by the increasing consumer demand for eco-friendly alternatives. Biodegradable color masterbatches, which are essential for enhancing the aesthetic appeal of sustainable plastics, utilize natural pigments and polymers that can decompose without leaving harmful residues. This advancement not only meets regulatory requirements but also satisfies the environmentally conscious consumer.

Furthermore, the formulation of these masterbatches often involves the use of renewable resources, such as plant-based starch and cellulose. A study published in the Journal of Cleaner Production highlights that integrating biodegradable additives with conventional plastics can improve the material's lifespan while maintaining its utility in various applications, from packaging to consumer goods. This dual functionality creates a compelling case for manufacturers to adopt biodegradable solutions, ensuring that their products are not only visually attractive but also aligned with global sustainability goals. The shift towards biodegradable color masterbatches is not just a trend, but a crucial step towards minimizing the environmental impact of plastic waste.

2025 Top Trends in Color Masterbatch for Sustainable Plastic Solutions

This bar chart illustrates the projected adoption rates of various innovations in biodegradable color masterbatches for eco-friendly plastics by 2025. The data highlights a growing preference for natural pigments and recycled materials, reflecting the industry's shift towards sustainability.

Impact of Regulatory Changes on Color Masterbatch Production Practices

The demand for sustainable plastic solutions has prompted significant regulatory changes that are reshaping color masterbatch production practices. According to a recent report by the Global Plastics Alliance, nearly 60% of manufacturers are anticipating tighter regulations concerning the environmental impact of plastic products by 2025. This shift is driving companies to innovate and adapt their production processes, emphasizing the need for eco-friendly raw materials and reduced carbon footprints in color masterbatches.

Furthermore, as governments implement stricter regulations on plastic waste and emissions, manufacturers are increasingly turning to biodegradable and recyclable materials. A study published in the Journal of Sustainable Plastics found that the use of recycled content in color masterbatches could increase by up to 40% over the next five years. This not only aligns with regulatory demands but also caters to consumer preferences for sustainable products. Companies are investing in technology to formulate color masterbatches that meet these new standards while maintaining performance and aesthetic qualities, thus ensuring compliance without compromising on product quality.

Consumer Preferences Driving Color Choices in Sustainable Plastics

In recent years, consumer preferences have significantly influenced the color choices in the realm of sustainable plastics. As environmental awareness continues to grow, consumers are increasingly demanding products that not only meet their aesthetic needs but also align with their values regarding sustainability. This shift has prompted manufacturers to rethink their approach to color masterbatch formulation, focusing on eco-friendly pigments and processes that minimize environmental impact. The desire for vibrant, appealing colors remains strong, yet it is now coupled with the need for transparency and sustainability in sourcing materials.

Moreover, the burgeoning interest in recyclability and biocompatibility is transforming color trends within the industry. Sustainable plastic solutions are increasingly incorporating natural colorants and biodegradable additives, ensuring that the final products do not compromise environmental integrity. Additionally, consumers are now more inclined to choose products with colors that express individuality while still adhering to sustainable practices. This trend exemplifies a shift in market dynamics where color is not just about visual appeal; it's also about a commitment to responsible consumption and environmental stewardship, driving the development of innovative materials that reflect the growing importance of sustainability in consumer choices.

2025 Top Trends in Color Masterbatch for Sustainable Plastic Solutions

| Color Choice | Sustainability Factor (%) | Consumer Preference (%) | Market Growth Rate (%) |

|---|---|---|---|

| Green | 80 | 55 | 12 |

| Blue | 70 | 53 | 10 |

| Earth Tones | 75 | 48 | 8 |

| Pastels | 65 | 50 | 9 |

| Neon | 60 | 32 | 6 |

Future Outlook: Integrating Color Masterbatch in Circular Economy Models

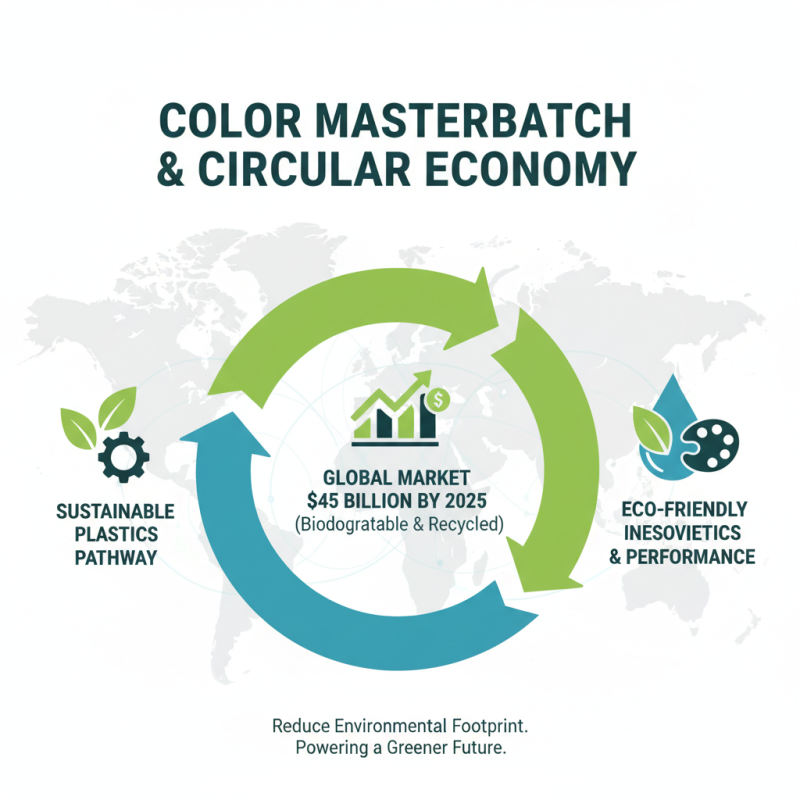

The integration of color masterbatch into circular economy models presents a promising pathway towards sustainable plastic solutions. As industries increasingly commit to sustainability, the demand for eco-friendly alternatives has risen significantly. According to a recent report from the Global Polymer Association, the global market for biodegradable and recycled plastics is projected to reach $45 billion by 2025. This shift is catalyzing innovations in color masterbatch formulations, enabling brands to reduce their environmental footprint without compromising on aesthetics and performance.

Implementing color masterbatch in a circular economy framework involves utilizing recycled plastics and designing materials that can be reused or recycled effectively. Data from the Ellen MacArthur Foundation reveals that improving recyclability can decrease plastic waste by up to 50% in some sectors. By adopting these practices, manufacturers can not only contribute to a more sustainable supply chain but also appeal to a growing consumer base that prioritizes sustainability in their purchasing decisions.

Tips: To effectively integrate color masterbatch in circular models, consider collaborating with suppliers who specialize in sustainable materials. Additionally, invest in research and development to explore new biodegradable pigments that can reduce environmental impact. Lastly, educating your team on sustainability practices can enhance the overall effectiveness of these initiatives.

Related Posts

-

What is Color Masterbatch and How It Transforms Plastic Manufacturing

-

Unlocking Creative Potential: How Color Master Batches Transform Plastic Manufacturing

-

How to Choose the Right Plastic Color Masterbatch for Your Projects

-

Ultimate Guide to Choosing the Right Compound Masterbatch for Your Projects

-

What is the Plastic Effect and How Does it Impact Our Environment

-

Unlocking the Future of Plastics: How Anti Block Masterbatch Enhances Packaging Performance